Updated: 03-Jun-2025

Turbomeca was founded in 1938 by J. Szydlowski and Mr. Planiol.

-Both were experts in compressors and turbocharger turbines, aiming to supply construction companies, especially Hispano-Suiza.

-After WWII, they began manufacturing small turbojets, turboshafts, and turboprops based on Szydlowski's patents (Szydlowski Brevets).

-Fast forward in time, in 1987 Turbomeca joined the Labinal group. After Szydlowski's death.

"Turbomeca logo"

-Later, in 1996, it was fully integrated into the new Sopartech Labinal corporation, which also includes Microturbo.

Labinal was associated with Snecma, so the latter deals with larger engines, Turbomeca with medium-sized aircraft and helicopters, while Microturbo specializes in small engines for missiles, RPVs, etc.

Finally, in 2005, everything was subsumed under the Safran Group.

"Safran Group Logo"

The importance of Turbomeca engines is demonstrated by the number of licenses it has granted throughout its history.

Notable among these are those granted to ENMASA, Bet-Shemesh, Blackburn-Rolls-Royce, Teledyne-CAE and China (SMPMC).

International collaboration with companies for joint projects includes, for example, Rolls-Royce for the Adour engine and the RTM-322; RR and MTU for the MTR-390; and Snecma for the Larzac.

"Marborés in Bordes"

Turbomeca was originally founded in Paris, but at the beginning of WWII it moved to Bordes in the Lower Pyrenees, where its main facilities are located.

Later, it would open other facilities in Tarnos (Landes).

The first engines appear to have been the 110 hp Turbine 782, the Oredón, and the Artouste.

The production of this brand is listed below, in no apparent order of insertion in this text.

"Oredon, with alternator"

The Oredon was an onboard auxiliary unit capable of supplying alternating electrical power, delivering 60 hp at an altitude of 7,000 meters, which is about 100 hp on the ground.

-The Oredon I already produced 160 hp in 1950.

“Oredon III”

-The Oredon rotated at 35,000 rpm and, using reduction gears, reduced it to 12,000 rpm, or even 6,000 rpm.

-It has a single-sided centrifugal compressor.

-It has two turbines, one with 20 blades and the second with 27.

-The speed governor is an isodromous piston and maintains the speed at approximately 0.4%, regardless of the load.

-The fuel pump is a Marin-Moulet vane pump.

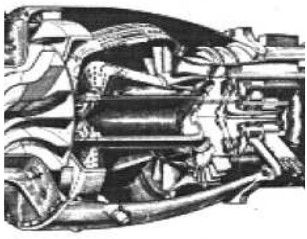

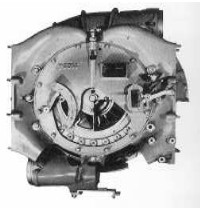

"Turbomeca Chamber"

-The main feature of all Turbomeca engines—except for some more modern ones—and patented by Szydlowski, is their combustion chamber and their system for delivering pulverized fuel through a sprinkler formed by fine holes in the main shaft.

-To ensure that the fuel reaches the interior of the chamber, it has a special shape, colloquially known as a “mushroom.”

“Exterior and interior of the chamber”

-The Oredón weighed 83 kg and measures 52 cm in diameter and 80 cm long.

-We will discuss the Artouste's life-sequence later.

“Pimené”

-The small Pimené is sometimes confused with the Palas in recent texts. It was designed in 1948, and it flew on a Fouga Cyclone glider the following year.

The Pimené was built in record time, accepted in April, the first one was bench-tested the following month, the second in June, and the third in July.

The fourth and fifth of this first experimental series were launched in August.

“Pimené 3”

With further improvements, the 5 was tested in Chalais Meudon on November 25, 1949, to pass certification tests. It lasted 150 hours and produced 110 kgf of thrust.

In 1950, the Fouga "Sylphe" glider was presented in Miami. It was the first turbojet-powered glider and caused a lot of sensation.

The Palas was built in 1950 and approved in 1951. It was a development of the Pimené, with 160 kgf of thrust for a dry weight, with standard equipment, of 69 kg. The diameter was 405 mm.

“Palas”

It was used on the small SIPA 200 Minijet.

“Sipa, with Palas engine”

It was also used on the Fouga Gemeux II with two Palas engines. (The Gemeux I had two Pimenés.)

The proposed Gemeux with Palas is shown in the below illustration.

“Fouga Gemeux II”

- The Palas was also considered a support engine for the takeoff of larger aircraft such as the Bretagne, the Douglas DC-3, and the Curtiss 46.

"Palas Pod on a DC-3"

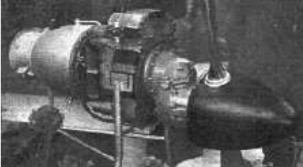

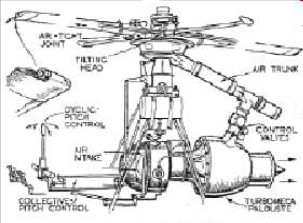

- The Palouste engine was an air turbo-generator specifically designed for helicopters, such as the Djinn.

“Djinn with Palouste”

The compressed air from the Palouste is directed to the tips of the blades, which rotate by reaction, through the rotor head. Under standard conditions, with the engine rotating at 34,000 rpm, it delivered 1,140 g/sec of air. Its diameter is roughly the same as the Palas, but it weighs 83 kg.

“Palouste”

“Palouste II”

Note the air outlet on the outer body of the combustion chamber.

“Palouste IV”

At this point, the air is compressed and hot, but not yet contaminated by combustion. This is point P3, where air is taken in on most turbines to humidify the passenger cabins.

A small arrow clearly indicates this point. We see a more than average-sized air outlet, as this engine's mission is to provide more air than thrust.

“Palouste IV”

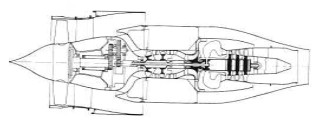

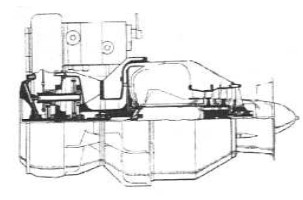

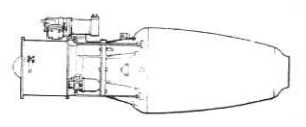

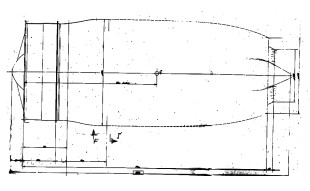

In this drawing, we see the Series IV engine, with the outlet nozzle and a generous venturi whose purpose is to control and stabilize the flow. Above the engine and at the level of the compressor, there is a small air-cooled, 2-stroke, starter engine.

“Palouste IV”

“Aspin”

The Aspin, version I, produced 200 kgf of thrust and was perhaps the first French turbofan, which flew on Fouga's Gemeux IV.

“Aspin I on Gemeux IV”

The Aspin II already delivered 350 kg of thrust and flew just 5 months later.

“Autan”

The Autan was a Palouste with an axial step added to the compressor, just in front of the centrifugal stage. This engine is from 1955 and it weighed 100 kg.

“Gabizo”

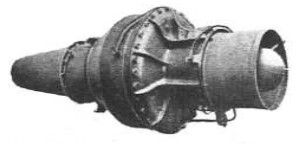

The Gabizo represented a leap in size, delivering 1,100 kg of normal thrust and 1,540 kgf with an afterburner manufactured by Nord-Aviation.

“Gabizo with afterburner”

-The Gourdon, like the Gabizo, dates from 1955.

“Gourdon”

-The Gourdon is a 660 kgf thrust turbojet, weighing only 172 kg.

-We see that the 1950s were extremely fertile years for Turbomeca. There were many other unknown enginess, such as the “Ossau,” a 100 kg thrust turbojet with a diagonal compressor, a combination of centrifugal and axial (see the Heinkel HeS-11). This engine is from 1952.

-Another unknown engine was the “Soulor,” which never flew and was a 1954 turbofan with 320 kgf thrust (Ducted Fan).

-The “Marcadeau” was another one that was barely shown. It was a 400-shp turboprop, derived from the Artouste II.

Turbomeca's success was undoubtedly the Marboré, which gave rise to a large family of turbojet engines that were manufactured in many countries.

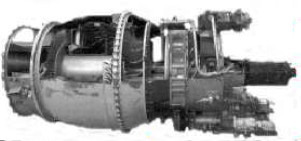

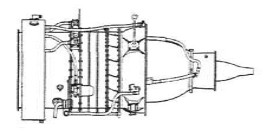

“Marboré II”

The two main branches were the II and VI. Both produced in series, such as the II, which was very extensive, as there were the IIC, D, E, F, etc.

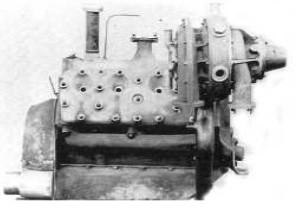

“Marboré I”

We see that one has a cone on the exhaust outlets and the other has a needle after the cone. These engines, manufactured by Teledyne-CAE in the USA, were the J-69s and were mounted on the Cessna T-37 and the Firebee, among others.

The Cessna T-37 Dragonfly was nicknamed "The Wistling Jet" due to the high-pitched whistling sound emitted by its air intakes.

The same thing happened—and still happens—with the Spanish Saetas, with engines manufactured by ENMASA in Barcelona.

“Marboré IIC”

“Marboré IID”

-The Marboré I was installed on the Gemeux III. The Marboré II produced approximately 400 kgf of thrust at 22,600 rpm.

“Marboré IIE”

“Marboré IIF”

-The Marboré VI, with slightly more power, approximately 1,060 lbf of thrust, was produced in smaller numbers than the Marboré IIs. Although it was significant, its success did not match that of the II, as the VI was quadrupled in number.

“Two Marboré VI engines”

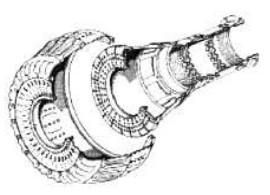

-Now we turn to the Artouste, which, as we mentioned, was one of the first to be produced. It started with model I, of which we offer the C model in cutaway.

-And the Artouste II and III, followed by some variants such as the B models.

-The Artouste II started with 400 shp at 33,000 rpm.

“Artouste IC, cutaway”

-The Artouste IIs have been seen, as turboshafts, in the Aerospatiale Lama SE315B helicopters and the Alouette II and SE316B helicopters. They already gave 870 shp.

“Artouste I”

-The IIB version continues with the same power and similar construction details and features.

“Artouste III”

- The Artouste III, with 550 shp at 34,000 rpm, increased its power, among other improvements, by adding an axial stage before the centrifugal compressor.

“The Artouste and the Artouste IIB”

“Two Artouste IIIB engines”

- We were able to compare first an Artouste and an IIB, and then two Artouste IIIBs.

“Arbizon”

- The Arbizon is another family of engines used in missiles such as the French Otomat.

“Arbizon II”

“Arbizon III y IIIB”

The Arbizón engines began production in 1956, with 250 kgf of thrust at 34,000 rpm. By 1970, the Arbizón IIIB was already delivering 380 kgf.

-The simplified version of the Arbizon was the IV, with 367 kgf of thrust.

“Arbizon IV”

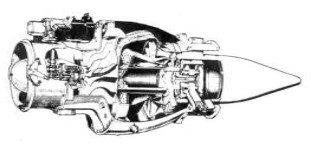

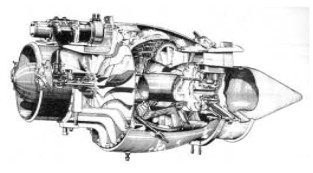

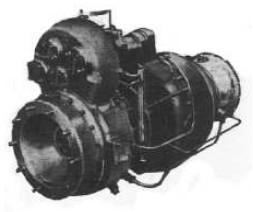

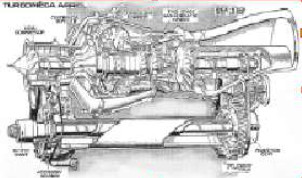

-At the same time as the Arbizon was being launched, another important turboprop, the Bastan, was also launching.

-The initial power of these engines was 650 shp, plus 80 kgf of thrust.

-Eight years later, in 1965, the Bastan VII model reached over 1,000 shp.

“Bastan with open cowling”

For example, the last version of the Bastan VII intended for the Nord-262 aircraft gave 1,130 shp.

Below is a demonstration Bastan (Demo) on its exhibition stand, with a shortened propeller.

"Beautiful front of the Bastan"

“Bastan VII for the Nord-262”

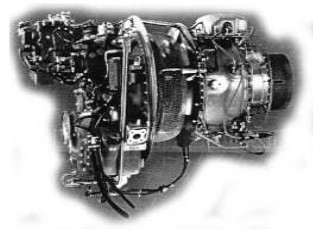

The twin-Bastan or Bi-Bastan is a helicopter coupling using a reduction gearbox and an angled output toward the mast.

“Twin-Bastan”

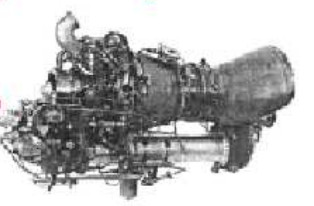

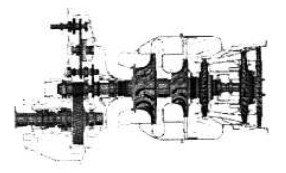

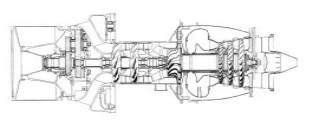

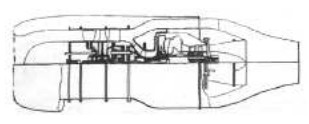

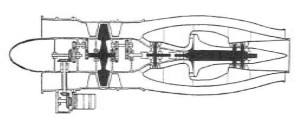

Now we come to the Turmo, which is a derivative of the Artouste I, developed since 1950.

In this engine a power turbine and gearbox were added.

“Turmo IIIB”

-The 1954 Turmo II produced 400 shp. However, versions III and IV had already increased the power to 1,600 shp.

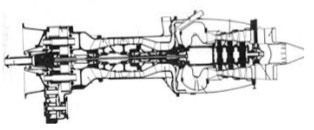

"Turmo IIIC, cutaway"

"Turmo IIIC”

-The Turmo's power output is at the rear.

-For the Breguet 941 aircraft, the Turmo IIID has a modified output so that, even though it originates at the rear, a transmission transmits power to the front of the engine.

-The Breguet 941 is a propeller-driven aircraft, although unconventional.

“Turmo IIID”

“Turmo IIID, for the Breguet 941”

-The Turmastazou is a combination of the Turmo engine and an Astazou.

“Turmastazou”

-The Turmastazou XIV is a free-turbine turboshaft with an output of 889 shp.

-For helicopters, a Double-Turmastazou was made by joining two XIV engines, producing 1,775 shp through a common gearbox shaft.

-Another version with a Turmastazou XVI increased its output to just over 2,000 shp.

-The Astazou engines have also been highly successful.

"Astazou II, cutaway"

-The most famous installation of these engines was in the Pucará aircraft of the Argentine Armed Forces, which were used during the Falklands War.

"Astazou without propeller"

-It comes in various turboprop and turboshaft versions. The latter is used in Aerospatiale's Dauphin I helicopters.

“Astazou XVI”

-Astazous models, such as the XX model, produce 1,400 shp. The XX A, 1,295 shp, etc.

“Astazou XIV”

"Astazou II turboprop"

“Astazou XIV-XVI”

"Astazou on display"

-Astazou models have been seen on the Pilatus Turboporter, Hirondelle, Jetstream, Alouette III, etc. The XIV produces around 850 shp.

The Astafan is a turbofan based on the Astazou and the Model II has variable-pitch fan blades. It delivers 765 kgf of thrust with water injection.

“Astafan”

Arius. Often confused with Arrius, the former refers to air generators for helicopter blade propulsion.

The Arius I supplied compressed air to the blade tips of the Ariel SO-1120 helicopter, where the combustion chambers were located. The Arius produced 280 shp at 36,000 rpm, delivering an air flow rate of 1,260 g/s.

The Arius II delivered 1,800 g/s.

The Arrius engines are turboprops and turboshafts.

“Arrius turboshafr”

Previously known as the TM-319 (which we'll discuss later), the turboshaft version did not use the Szydlowski combustion chamber system, but rather a more classic or Standard one.

“Arrius, cutaway”

The similarity to the TM-319 is extraordinary.

“Turbomeca, TM-319”

-The turboprop version of the TM-319 looks like this:

“TP-319”

“Another TP-319”

-We present again one of the latest Arrius, the one fitted in pairs on the Agusta A-109 Power and the AS-355 Ecureuil of Aeroespatiale.

“Arrius”

- The Arriels are also turboshafts and are used in the latest important helicopters such as the AS-350 Ecureuil, AS-550 Fennec, AS-365 and AS-565 Dauphine and Panther respectively, the Agusta A-109K, and the Sikorsky S-76A and C.

- The Arriel 1S ranges from 700 shp, generally starting with the 1A, and the 1M or 1D ranges between 650 and 750 hp.

“Arriel 1S”

- The Arriels have a modular construction, making maintenance much easier.

“Two different types of Arriels”

-The Arriels of the Dauphine AS-365/HH-65 in pairs are the 1C2/C2/2C2CG or 1M1.

-Other aircraft also have them, such as the S76 series, the H410 and H425, and the Eurocopter 155B.

“A final version of the Arriel”

-The Aubisques don't seem to have had a significant impact within the company. However, there's no doubt that they're all experiments. They would be a step closer to the Adour and Larzac, which we'll also see.

“The Turbomeca Aubisque”

“Another View of the Aubisque”

-The Aubisque was a ducted fan engine that developed 700 kgf of thrust at sea level (SL). It was designed to power the Saab 105.

-The Turmo turboshafts are large, having existed since the beginning of Turbomeca, but have since been replaced by the Makila, with almost 2,000 shp.

“Two Makilas”

-Despite their size and power, the Makilas retain the same architecture as all Turbomecas, as we can see in the cutaway below.

“Makila cutaway”

-The Makilas are seen on the Eurocopter EC-225 and EC725. Also on the Rooivalk (see Topaz).

-Below we see one of the most recent Makilas used by these helicopters.

“A recent Makila”

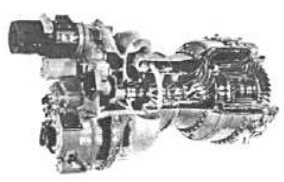

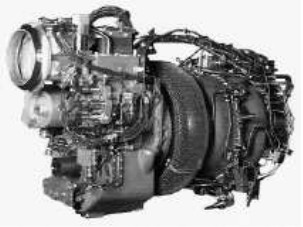

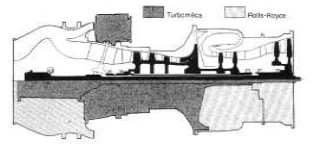

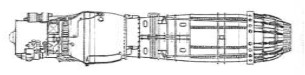

-Other turboshafts have been built in collaboration with other companies. For example, the RTM322, made with Rolls-Royce, has between 2,100 and 3,000 shp. The basis of the new "Aneto".

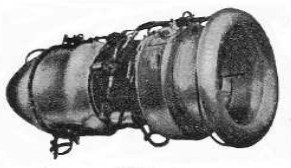

“RTM-322”

-The first test was conducted in 1985. The first flight was in 1986, and certification was achieved in 1987.

"Another view of the RTM-322"

-At first, the plan was to make a turboprop based on the RTM-322, and the project was named RTM-322-06.

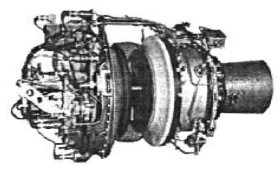

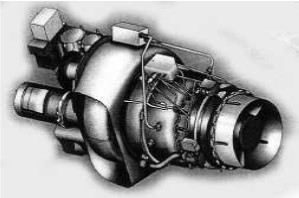

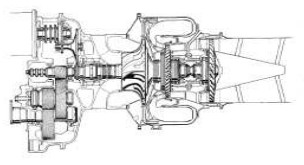

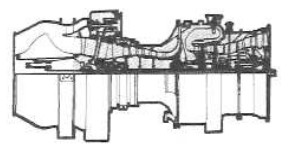

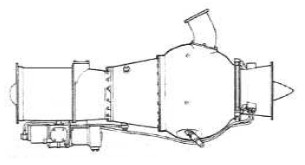

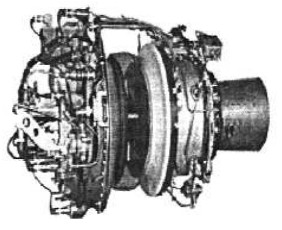

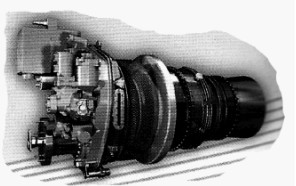

-The MTR-390 engine is a collaboration between MTU, Turbomeca, and Rolls-Royce.

“MTR-390”

-The MTR-390s are intended for Tiger attack helicopters (HAD, UHT, etc.).

-When Turbomeca started, a little-known project was the 815-hp A-129 engine, as were the TAAs, in collaboration with the Italian helicopter manufacturer Agusta, and the TAA-230, with 350 shaft-hp.

-Another engine is the MTM-380, in collaboration with MTU. It is a free-turbine turboshaft.

-The RTM-321, a twin-shaft turboshaft for 1,500–2,000 shp, was also developed with Rolls-Royce.

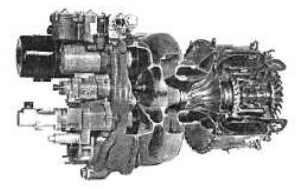

“TM-333”

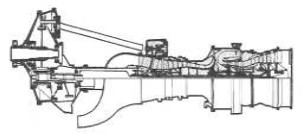

-The TM-333, certified in 1986, was designed to succeed the Arriel and to be installed on the twin-engine Dauphin. It also powers the SA-365M Panther.

“TM-333”

-Let's move on to turbojets that generally have nothing to do with the Turbomeca production line, but which were inspired by the Aubisque's architecture. These are the Adour engines, built in collaboration with Rolls-Royce.

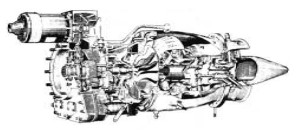

“Turbomeca-RR, Adour”

-The Adour is the engine of the European Jaguar fighter jet. It has two shafts: the HP and the LP (High Pressure and Low Pressure) engines. It delivers 2,000 daN (decaNewtons) dry and 3,000 with afterburning.

-The Larzac is another engine built in cooperation, mainly with Snecma , but also with the German companies MTU y KHD.

-All of them forming what is called a GRTS or "Groupement d'Interés Economique" (another form of what we know as a UTE, or Temporary Union of Companies), united to achieve a common goal.

“Larzac”

-The first Larzac entered the program in 1969, and the first bench test was conducted in 1972.

-The Larzac is known as the Larzac 04, and the 04-C6 and 04-C20 versions have been produced. The -C6 version delivers 1,318 daN of thrust, and the -C20 delivers 1,412 daN.

“Another view of the Larzac 04-C20”

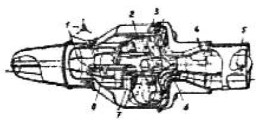

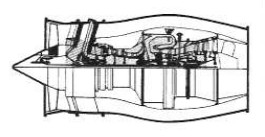

Turbomeca's latest release is the Ardiden, a turboshaft for 5-6 ton class helicopters.

“Ardiden Architecture”

As we can see, this is an engine in which the gas generator has a turbine and two single-sided active compressors in cascade. Two power turbines then pass through the gas generator shaft and reach the front reduction gear. The accessory box is located above it. It has a power output of approximately 1,200 shp.

The Ardiden 1H/Shakti, which is the name given to the engine installed in the Dhruv helicopter (two engines).

“Ardiden/Shakti”

-The Arrius, Arriel, Makila, Ardiden, MTR-390, TM-333, and RTM-322 are currently being developed for the new Eurocopter helicopters, the European company that replaces other brands such as Bolkow, Sud-Aviation, Aerospatiale, etc.

-Turbomeca Industrial has air generators adapted from the Pimedon, Palouste, Arrius, Alizé, AST-600, or the Aután II.

-This is the end of the Turbomeca chapter from the first edition, published in 2003. Since then, additional information has been gathered from various documents and visits to museums in Europe, which we provide below.

-A significant batch of engines from this brand are on display at the CAEA (Conservatory of Air and Space of L’Aquitaine).

In addition to this brand, there are a couple of rotary engines, P&W fixed radial engines, and a magnificent cutaway Hercules, RR RB-162, M-53, an assortment of Atar 9, H-S Nene, and Verdon (formerly Tay), Mirage rocket engines, etc.

The engines are very well displayed as cutaway in a very educational way. This can be seen in the illustrations below.

"Palouste Turbogenerator" (PeT)

"Gabizo Turbojet" (PeT)

Explanations of these two engines are provided in the main text. The next engine is the Bastan, also cutaway or "éclaté" as it is described.

"Bastan Turboprop" (PeT)

The below Astazou is a 440 kW XIV M.

“Astazou XIV M” (PeT)

-Turbine rotation is at 43,000 rpm, with the output shaft revolutions at 6,334 per minute. It uses a multi-gear reduction.

“Cross-section of the above Astazou”

-The complete schematic section includes the reduction gearbox and the general engine layout.

-The Marboré II and VI are on display, well known from the main text, although we take the opportunity to include two cutaway drawings.

“Marboré II”

“Marboré VI”

-Also on display is a Turmo III turboprop turbine, in this case from the Breguet 941 aircraft. As well as an Artouste II from the Alouette helicopter.

“Artouste II”

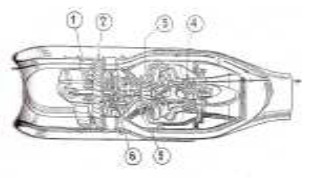

-There aren't many publications or illustrations of dual-flow Aspin engines, so it was important to locate the ones shown below. This is the Aspin I from a 1951 Spanish publication.

-It is presented as a combination of a turbojet and a turboprop, it is a predecessor of today's turbofans.

“Aspin I Engine”

-In (1), there are the non-rotating, directional blades with variable incidence to regulate the airflow to the engine.

-In (2), there is the the fan, with a reducer.

-In (3), the centrifugal compressor.

-In (4), a double turbine.

-In (5), the drive coupling for the fan reducer.

And in (6), the reducer itself.

“Aspin I, exterior view”

-There is an unknown Turbomeca engine called “Turmalet.” Research is going on.

-The Astafan was developed from the Astazou, of which we now have new versions.

-The Astafan IV F-6 diagram. It delivers 1,070 kgf of thrust.

“Astafan IV F6”

-The Astafan IIBs gave 715 kgf of thrust. The IIIB was increased to 785 kgf and the IVB to 1,020 kgf.

-It was based on the 1030 kW Astazou XX, the IV had a 13-blade fan added.

“Astafan II 6”

-The Astafan II 6, with only 700 kgf of thrust, was based on the Astazou XVII.

“Astafan II 6”

-Just as this version exists, research is continuing to locate information on the Bastafan, the Fan version of the Bastan turboprop. Others mentioned that the Turmalet and the Tramontana are also available.

-Many preserved Turbomeca engines are located in the MAE reserve warehouse. Some have been restored or prepared as cutaways, like the Marboré and Bastan we offer now.

“Turbomeca Corner”

“Marboré cutaway and Bastan with a foreign exhaust pipe

underneath it—possibly from a Cessna Caravan”

“One of the most interesting applications of Turbomeca engines is the Palouste air generator on the Djinn helicopter.

“Djinn at the Le Bourget Museum”

“We can see that the combustion chamber casing is voluminous and of a certain capacity. A duct extends from it, leading via a stopcock to the rotor head.

-Assuming an interesting engineering feat in this head, it conveyed the air, without pressure loss, through the interior of the blades to an outlet on the marginal edge directed backwards, similar to the ROR (Rocket On Rotor) system.

"Blade tip outlet"

New chronological list.

From Appendix 6: We have information mentioning the "Highlights" the company has had in its 20th-century history.

-1938. Founded by J. Szydlowski, it was based at the Salmson facilities in Boulogne-Billancourt. It prepared compressors for supercharging engines.

"TC-1 Compressor"

-It also supercharged Hispano-Suiza engines such as the 12Y-Z89 with the S-39H31 centrifugal compressor. About 2,000 units of this type were made.

"Hispano Suiza 12Y-Z89 Supercharger"

-1939. Production moved from Salmson to Mézières-Sur-Seine.

-The 12Y-45s were also supercharged. But in the tests required for their development, the first superchargers were installed on standard automotive engines, as seen in the American Mercury engine below.

-1940. Faced with German pressure, Turbomeca moved to southern France, to St. Pé de Bigorre, where the Mercury automobile was tested in 1941.

“Mercury with TC-1”

-1942. New facilities in Bordes, near Pau. Mr. Szydlowski sought refuge in Switzerland, entrusting the factory to Mr. Martinot-Lagarde.

“S-39 Parts at the Bordes Factory”

-Tests continued for supercharging aircraft engines, such as the Argus AS10 with the S-39.

"Argus AS-10 with S-39 compressor"

-1942 and 1944. German occupation and engine production for the Germans (in the case of the Argus-10). They will bring the machinery, which will be renovated after the liberation. Szydlowski returns.

-1946. After the war, work begins on axial compressors and PV-19B superchargers. The Ministry orders the construction of gas turbines, which can be carried out thanks to the arrival of German engineers and technicians.

-1947. The Ministry specifies that the turbine must have a generator capable of operating up to 6,000 meters. The TT-782 is born.

-1948. The TT-782 is tested. It would be the prototype for the "Oredon" (see main text).

“TT-782 Prototype”

“First consignments of Oredon engines”

-The generator was from Alsthom, rotating at 12,000 rpm.

-1948. The first Pimené was tested, and the following year the Aspin prototype, with dual flow.

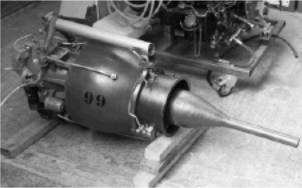

“TD-100-189, Aspin prototype”

“Aspin I”

“Aspin II”

-In 1950, the Palas, Marboré I, and II appeared.

-1951. A fruitful year for the brand, the Arrius II turboshaft, the Pimedón, the Aspin I, the Artouste II, and the Turmo I were tested.

- Licenses were granted to Fairchild for the Oredón. Also to Yugoslavia for the Oredon.

- Licenses were granted to the American company Continental for the Pimene, Palas, Artouste, Marboré, and Aspin.

- 1952. Licenses were granted to Blackburn of England (see).

"Aspin III compressed air turbocharger"

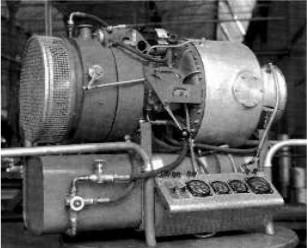

- 1953. The Palouste was installed on the SO-1220 helicopter, the famous Djinn. A Palas was modified to develop the Gabizo, and the first Marcadeau turboprop was also tested.

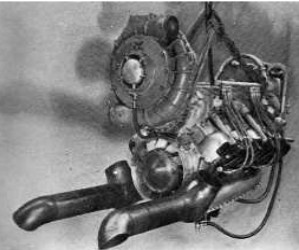

"Marcadeau bench test"

-1954. The Gabizo proved to be the brand's first engine with a thrust greater than 1,000 kgf. A 3,500 kgf turbine was built, coupled with a Nene turbojet, and was used to power a Navy starlet.

- The Spanish company ENMASA was granted a license for the Marboré for the Saeta aircraft.

- In 1955, the Gourdon was tested for the American company Continental.

- In 1956, Turbomeca and Hispano-Suiza founded the company CGTM (Compagnie General des Turbo-Machines) for flight testing of their engines.

- 1957. This was the year of the Bastan.

“360 SHP Turmo II for the Alouette II”

“Turbomeca Gabizo”

“Arbizon, 250 Kgf”

The Arbizon is a derivative of the Palas, incorporating a single-stage axial compressor before the centrifugal compressor.

-In 1958, the Astazou turboprop was tested.

-1959. The Marboré VI was launched and the Astazou II was tested.

-1960/61. The Astazou continued to be tested, and the licensing agreement with Continental was renewed.

-1962. This was the year of the Aubisque for Sweden. The Artouste III was licensed to HAL in India.

-1964. Operations began at the new Tarnos factory near Bayonne.

"The Tarnos factory"

-In 1965, a company was founded in conjunction with Rolls-Royce to manufacture the Adour. Industrial engines based on aircraft engines began to be produced.

-The Puma helicopter was powered by Turmo III engines, and the subsidiary Ormat Turbines Ltd.. was established in Israel.

-1966/67. The Bastan VII is tested. And the first Adour is tested in Tarnos.

-1968. Bet-Shemesh Engines Ltd, a subsidiary of Turbomeca, is created to produce the Marboré, Turmo, and Astazou.

-Now we show the recently developed Aquitania, an engine that supplies compressed air and electrical power.

"The Aquitania was bench-tested in 1960."

-In 1969, Turbomeca and Snecma founded GRTS to manufacture the Larzac. The Turmo IIIF was also tested on French SNCF railways. The Astazou IV was also installed on trains, including American Amtrak.

-1970. IHI was licensed for the Adour. In 1971, tests continued on high-speed TGV trains with Bi-Turmo IIIGs.

-1972/73. Tests continued on TGV trains, reaching speeds of 318 km/h with Bi-Turmo IIIGs. The Larzac and the Bastan-Gaz VI industrial turbine were also tested.

-1974/75. Tests of the Arriel were carried out on Gazelle, Dauphin, and Ecureuil helicopters.

-1976. The Makila was tested.

-1977. The Astadyne group was founded with Abeg-Semca and Turbomeca to build APU/APP auxiliary power units. MTU/Turbomeca and Turbomeca do Brasil were also founded.

-1978/79. The Fouga 90 flew with the Astafan IIG and IVGs.

"Alizé Turbocharger, 1969"

-1980. This year marks the creation of a subsidiary in the USA, TEC, or Turbomeca Engine Corporation, in Dallas.

-1981. Testing of the TM-333 and AST-600.

-1982. Signing of a cooperation agreement to build the Larzac-04 C20, between Turbomeca, Snecma, MTU and KHD.

“Turbomeca AST-600”

-In 1983, a marketing agreement was signed with General Electric for the TM-333. The first tests of the TM-319 were conducted.

-1984/85. The AST-950 was built in cooperation with ABG-Semca. The TM-307B turbocharger is tested to power diesel engines.

“TM-307B”

-1986/87. The TM-322 is tested on a Sikorsky S70. Turbomeca and Labinal are merged through a share capital merger.

-In Finland, Redigo training aircraft are flown with the TP-319.

“TP-319 Turboprop”

-1988. Mr. Szydlowski dies on the 50th anniversary of Turbomeca.

-1989. Labinal acquires all of Turbomeca. A contract is signed with Oto Melara to develop the Arbizou IIID.

-Labinal makes an agreement with Sundstrand to establish APIC to build auxiliary units.

“MTR-390 for the Tigre Helicopter"

-1990/91. Turbomeca Asia Pacific and Turbomeca Germany are created. CGTM is fully taken over.

"The TM-319 is named after Mount Arrius"

-1992. Turbomeca Sud-americana is created. First Eurodyn test.

-1993/94/95. Turbomeca engines appear to be specialized for use in helicopters. Arrius, RTM-322, Arriel engines, etc.

-Creation of Turbomeca Australasia. Acquisition of a 51% stake in Microturbo (by Labinal).

-1996/97/98. The first flight of the Russian MiG-AT fighter jet with two Larzacs is notable.

-The Makila 1K2 flies at the South African Rooivalk.

-Creation of the Turbomeca Japan Kabishiki Kaisha.

-Information about Turbomeca has increased significantly after a visit in July 2009 to the "Ailes Anciennes de Toulouse," where we were able to locate several engines of this brand.

-Even cutaways and with well-colored parts, as if they had belonged to the same factory as exhibition engines. Although they lacked luster, some were half in the open.

-Below we show a repertoire of successful engines:

“Artouste III”

“Turmo III”

“Bastan, 750 CV”

-The Bastan is a derivative of the Artouste III.

“Marboré VI”

“Turmo IIID”

“Autan II”

“Aubisque”

“Turmastazou XIV, 850 CV”

“Bi-Turmo IIIG, from the TGV train”

“Astazou IV-A for turbotrain”

“Artouste IIIB, 570 CV”

“Astazou XVIII and XX, 1018 CV”

“Astagaz XII 400 kW industrial,

installed at Turbomeca's Tarnos factory”

“TI-255 175 kW industrial turbine”

The TI-255 is a derivative of the Astazou II. The Bastan has also been manufactured in a Bastangaz version.

“Bastangaz VI, 550 kW”

“Bastangaz VII, 750 kW”

“Oredon IV”

-The 120 kW Oredon IV variant was built in series to equip the Shahine armored vehicles, in 1975.

-The 120 kW Turmo XII for the SNCF turbotrain.

“Turmo XII for TGV trains”

“Bi-Bastan VII, 1620 kW, industrial”

“MTM-380 turboengine, 1000 hp”

“TM-319, 450 CV”

“Turmo XII for TGV trains”

“MTR-390, 1300 CV”

“Eurodyn”

-The Eurodyn is an industrial turbine developed within the European Eureka program, comprising France, Norway, and Sweden.

-Note here that the APS-3200 turbines are the auxiliary service units used on the Airbus A-320. (APIC).

“APS-3200”

“AST-950, for the Breguet Atlantic”

“Bordes and Mézières-sur-Seine Factories”

-We now show an interesting example of engine localization. This is the Pimedón “Compressed Air Turbo-Generator,” built in 1950, providing an air flow rate of 450 g/s.

“Pimedon Air Compressor”

-Turbines are very well suited for air conditioning for the comfort of aircraft cabins.

-Initially, they provide hot, pressurized air, necessary for Pressurize an aircraft at altitude. Controls can achieve the appropriate values for each altitude.

-They can also be used to cool the same hot air exiting the engine compressor in so-called ACMs (Air Cycle Machines), which take advantage of the principle of rapid expansion to dramatically lower the temperature. They are almost always supported by radiator-type heat exchangers.

"Chasseur Expansion Turbine"

-By mixing part of the hot air exiting directly from the main engine with the cold air from the expansion turbine, we can thus control the temperature.

"Turbo-fan and Air Interchange"

-This air conditioning unit was used on the French Armagnac aircraft.

-This aircraft, being powered by piston engines and lacking turbines, used Turbomeca PC-15 compressors to humidify the cabin.

-When Turbomeca joined the Labinal Group, it changed its logo, the famous "Brevets" Szydlowski” by the one we show below.

“Turbomeca-Labinal Logo”

-Turbomeca is therefore a division of Labinal, as is Microturbo.

-But at the same time, Labinal belongs to SAFRAN, see.

-We know that the first Turbomeca engine was the auxiliary “Oredón”.

“The 140 HP Oredon with an alternator”

“Section of one of the first Oredons”

-The first jet was the Pimené, but it was initially presented as the TR-011, in 1949. It only produced 198 lbf of thrust.

“The TR-011, the basis of the Pimené”

-Another new photo of the Pimené with 220 lbf of thrust was obtained from an old brand catalog.

-The Pimené with 220 lbf of thrust

-As we can see, the Pimené is identical to the TR-011.

-Continuing with new views of this brand's engines, we have the first photograph of the Artouste, which would become a very important series, its development is continuing in new versions today.

“Primera Artouste”

“Turbofan Aspin I”

“Evidence of the Aspin I Bypass”

“Aspin II”

“400 hp Marcadau Turboprop”

“Palouste installation on a Djinn helicopter” (PeT)

-In the 1980s, a simpler version of the TM333 was made, the TM319.

-It does not have the axial stage of the TM333, and its power was slightly lower, at 500 shp, and it was installed in the first Ecureuil-2s.

“TM-319”

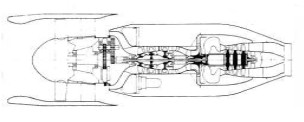

-The RTM.322 was built together with Rolls-Royce. It could be said that the "cold" part was made by Turbomeca and the "hot" part by RR. It will be the "father" of the 2018 "Aneto".

"Section with marked areas for each manufacturer"

-The RTM.322 was planned to be multipurpose, so the RTM.322-11 version was intended for turboprops, derived from the -01 turboshaft.

-While the RTM.322-20 version was a turbofan.

-This can be seen below in what we could call the design of the RTM.322 engine family. In the following three diagrams:

“RTM.322 turboshaft”

“RTM.322 turboprop”

“RTM.322 turbofan”

-And I recently read in an article: the names given to Turbomeca engines were, for turboshafts, named after the lakes of the Pyrenees Mountains.

-For turbojets, they were named after the peaks of the same mountains. By-pass engines are named after the "ports" (cols) of those mountains.

-And turboprops were named after their valleys.

-The "Soulor" is mentioned in the main text without any illustration. A photograph has now been located of this dual-flow engine, which is considered a "Ducted-fan," not a "By-pass" engine.

-It is clearly visible that around the annular combustion chamber there is another cowling that extends to the end of the nozzle.

“Turbomeca Soulor”

“Soulor diagram”

-Now we have received information about the existence of another engine, the “Tramuntana.” (A wind that blows strongly in the Perpignan area and northern Catalonia, over the eastern Pyrenees). Also missing is the “Tourmalet,” a legendary French mountain from the Tour de France.

-The Gabizo used afterburners, even with its small size, producing a maximum thrust of 3,395 lbf at 17,500 rpm. This is achievable with a slightly larger conventional turbojet.

“Gabizo with afterburner”

-The Autan was an air compressor. It takes air at pressure and temperature from outside the combustion chamber before entering it. Considered a “Palouste” type.

“Drawing of the Autan”

-And now a beautiful photograph of the Turmo 3D in a turboprop version for aircraft.

“Turbomeca Turmo 3D”

-We obtained a cross-section drawing of the Aubisque, which we reproduce below because it seems very interesting.

“Beautiful design of the Aubisque”

-The Astafan was tested on an American Aerocommander aircraft, as seen in the image below.

“Astafan Tests”

-A version of the Astafan with exceptional polishing of the “islands” or front struts.

“Beautiful assembly of the Astafan on another Aerocommander”

“Arriel turboshaft in Flight magazine”

-Exceptional drawing by John Marsden. Note the “mushroom” combustion chamber.

“TM333 engine of the Dauphin helicopter”

Turbomeca MTM385, derived from the TM333

From Appendix 9: In the Safran Group. The latest product, the Arrano, for 1100-1300 SHP helicopters.

“El Arrano”

From Appendix 10: For the author, there was a period of confusion and searching for an engine from this brand that seemed like a new model. It was the “Orphee.”

“Special Transport with an Orphee (Nord 510)”

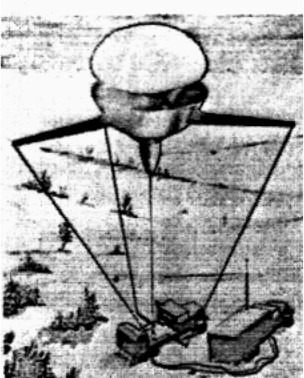

-It turned out that the “Orphee” is a captive vehicle, launched from a mobile platform and used to observe the surroundings from a certain height.

-The name “Orphee” comes from the acronym “Observation Radar for Helicopters,” in fact, today it would be a Captive Drone.

"System Layout"

This drone was a Nord 510 and was powered (in 1966) by a Turbomeca Astazou II in a vertical position driving a four-blade horizontal propeller.

“Turbomeca Astazou”

Perhaps due to this unusual position of this engine and the modifications it underwent, it was confused with the name of the captive vehicle, the Orphee, and was given the name Turbomeca "Orphee."

They also made the dual-flow engine, whose (illegible) measurements are shown in the following drawing. It is the Tourmalet engine.

The name Tourmalet is from a peak in the Pyrenees that has become famous because the Tour de France always passes through it. And it is a good mountain test for cyclists.

-The author imagines that, as always, Mr. Szydlowski went with his staff on excursions to the mountain range, and they decided to name the new engine after her.

“General outlines of the Tourmalet”

From Appendix 12: The times before the company's founding, and perhaps in its early days, Szydlowski had constant contact with Planiol, Rateau, Anxionnaz, and a group of experts in superchargers and turbochargers for piston engines.

-Szydlowski and Planiol were sent to the USA to work, using their expertise, on supercharging P-38 engines.

-At that time, they became interested in the L-1000 turbojet engine being developed by Lockheed and managed to bring back documentation and the project to develop it in their country. They had the support of none other than General de Gaulle. The goal was to create a super-fast fighter plane, designed by Payen.

The program was abandoned when, in 1946, efforts were directed toward the engine that Daimler Benz engineer F. Nallinger had designed, with no less than 7 tons of thrust, the B-701. Material and utilities were brought from Germany, in the final "distribution" of the war spoils. As it turned out, the project was also canceled the following year, in 1947.

But the starter motor, a small turbine, the B-781, remained, and that gave way to the "Oredon." See main text.

Turbomeca granted manufacturing licenses to several countries around the world. Here are two photos of engines listed for sale on eBay. They are a Palas and a Palouste. Perhaps English, manufactured by Blackburn.

“Turbomeca Palas with its characteristic extension”

"Palouste with its compressed air outlet"

Engines of TURBOMECA

Model: Adour (with Rolls Royce)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Alizé

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Aneto

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: APS-3200

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Aquitania

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Arbizon

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Ardiden

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Arius I, II

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Arrano

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Arriel

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Arrius

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Artouste

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Aspin I, -II

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: AST-600

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: AST-950

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Astafan

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Astazou

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Aubisque

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Autan

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Bastan

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Double Bastan

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Ennodyn

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Gabizo

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Gourdon

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Larzac M-49 (with Snecma)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Makila

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Marboré

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Marcadau

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: MTM-380 (with MTU)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: MTM-385 (with MTU)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: MTR-390 (with MAN and Rolls Royce)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Oredon

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Oredon II (with Rolls Royce)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Ossau

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Palas

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Palouste

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Pimedón

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Pimené

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: RTM-321 (with Rolls Royce)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: RTM-322 (with Rolls Royce)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Shatki (with HAL)(Ardiden)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Soulor

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Super Palas

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: TM-251

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: TM-319

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: TM-333

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Tourmalet

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: TP-319

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: TR-281

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: TT-782

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Turmastazou

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight:

Model: Turmo (Turbin Motrice)

Arquitecture:

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: / ---

Weight: