Updated: 20-Jul-2021

D. Napier and Son, Ltd was the full name of this company that manufactured printing machines from 1808, and from 1903 it built cars that became famous for their quality.

-In 1905 a Napier car raised the world speed record.

-By 1915 Napier began to build aircraft engines, first under license, the Sunbeam Arab and the RAF 3a, to continue with engines of their own design.

In 1942 D. Napier & Son was acquired by English Electric but still under its own name.

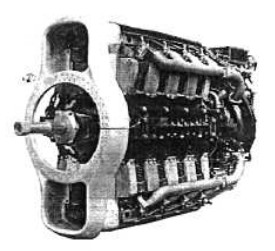

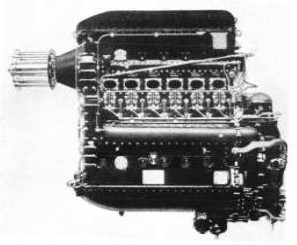

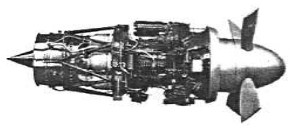

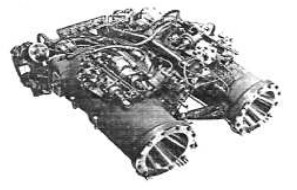

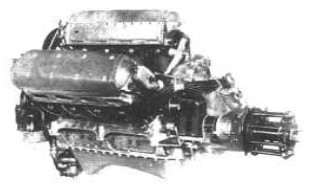

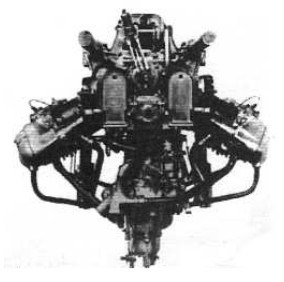

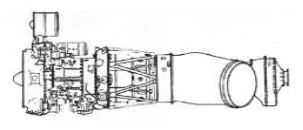

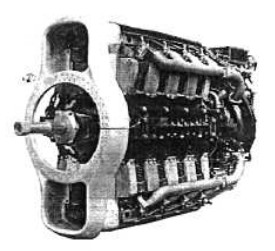

“Napier Lion 450 HP”

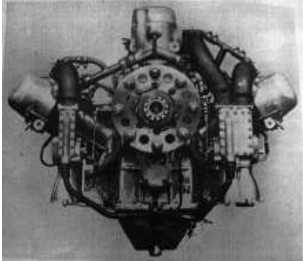

-The first one of their own design was the Napier Lion, introduced in 1917.

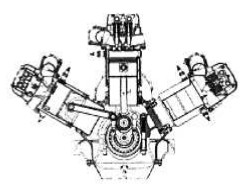

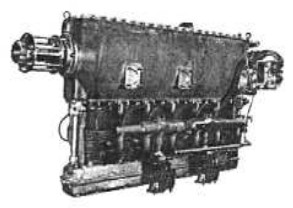

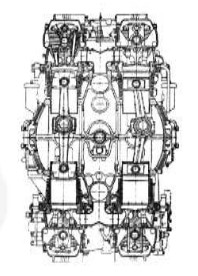

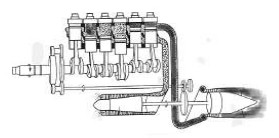

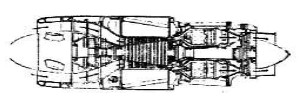

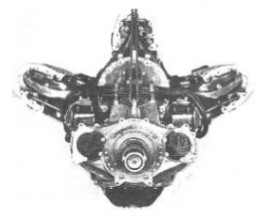

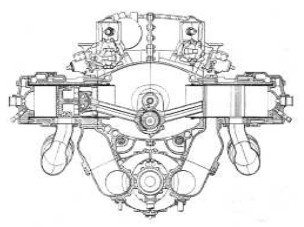

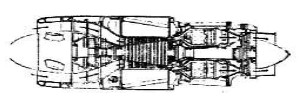

“Napier Lion schematics”

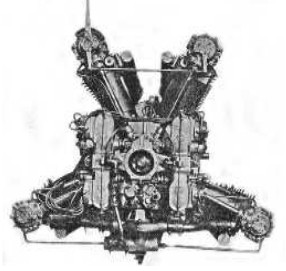

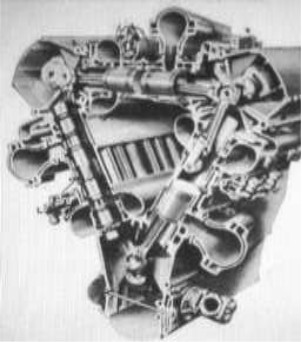

-It was a twelve-cylinder W engine, that is, with three rows of four cylinders. This formula made the engine 30% shorter and more compact.

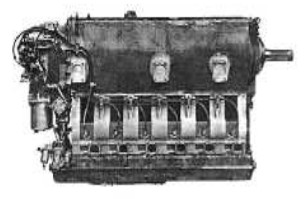

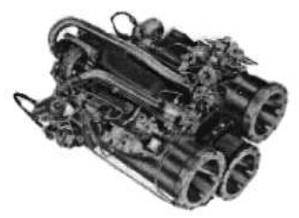

“Lion”

-Above all, the shorter crankshaft was subjected to less torsional stress. Although the W arrangement may look like it was going to be irregular, it proved not to be.

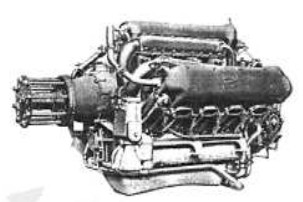

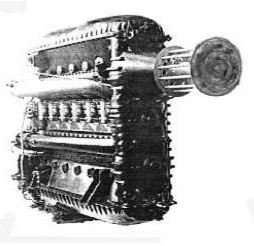

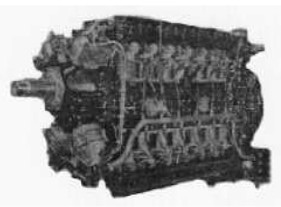

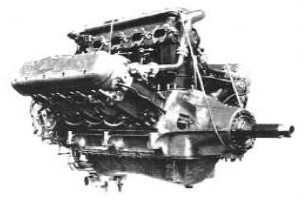

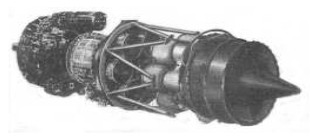

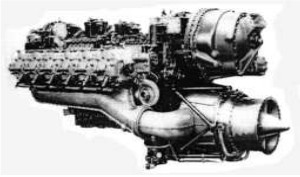

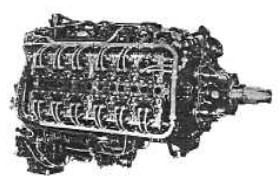

“Lion VIIb”

-Two rows of cylinders were as in classic V engines, but more open, while a third was sandwiched between them and standing upright. They had four valves per cylinder.

-The first Lion came out with 450 HP, that was very powerful for the time, although it did not intervene in the Great World War of 1914-18. It remained one of the best and most powerful engines years later.

-In 1919 it was already mounted on the DH-8 and -9, in 1920 on the Boulton Paul and Raf-21. In 1923 on the Blackburn Spotter, etc.

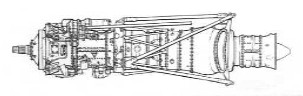

“Napier Lion, angled front view”

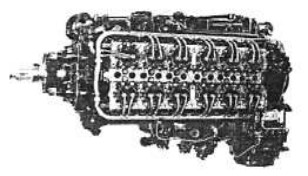

- There were several powers according to the use that was given to it. For example the Lion IIb of 1923 already raised the power to 470 HP. The 1927 Model VIII delivered 535 HP.

-The IX gave 500 HP. The X and Xa, 460 HP. The XI and XIa of the year 1930 delivered 530 HP. The XV gave 555 HP in 1932.

“Lion XI”

-One of the most notable successes of this engine (along with its participation in the Schneider Trophy) was equipping the Fairey IID aircraft, which alternated these engines with the RR Eagle IX.

-The Lion series V were the witnesses of the RAF flight to Cairo-Cape-England in 1926. The Napier Lion also powered the Spanish “Plus-Ultra” on its historic flight to Argentina.

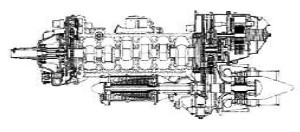

“Napier Racing Geared”

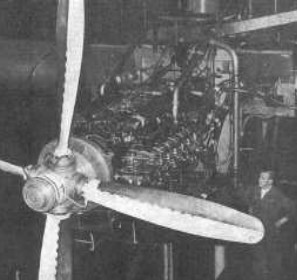

-During the Schneider Trophy from 1923 to 1927 the 800 HP “Geared Lion Racing Engine” was widely used on the Supermarine Seaplanes.

-Napier built the Sea-Lion, a marine version of the Lion aero engine that was used on the high-speed boats of the Air Sea Rescue Service.

“Napier Cub”

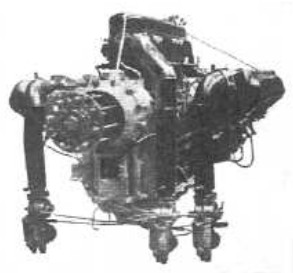

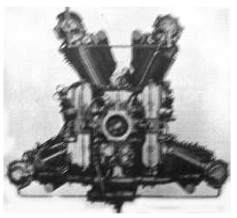

-The second design of the brand was the 16-cylinder Napier Cub and compared to the 12 in the Lion, the power output was 1,000 HP instead of the basic 450 HP of the previous one.

“Napier Cub”

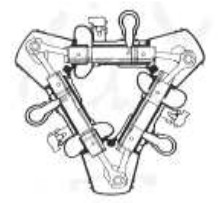

-It was a strange double V engine, that is, four rows of four cylinders, with 90° of phase between a row of the upper V and another of the lower V, being 52.5° the V formed between the two rows of upper cylinders.

-It was not used in great numbers, its best known application was on the Avro Aldershot.

“Napier Cub”

-From 1923 to 1930, Napier was very busy building the Lion, but the projects continued. The "Rapier" appeared in 1927, although it was not put into production until 1931.

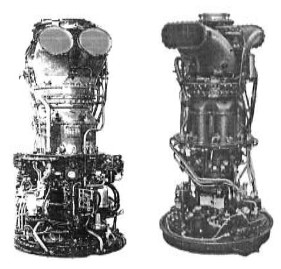

"Rapier without and with front fairing"

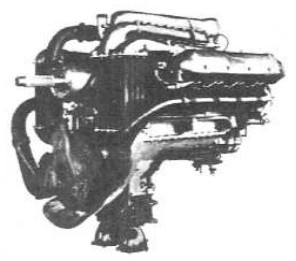

The Rapier was an air-cooled, supercharged, vertical H engine. It was rather small giving 380 HP with a high rotation speed at 4,000 rpm.

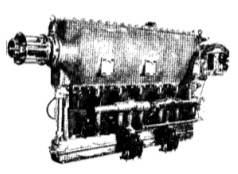

“Napier Javelin”

-At the same time as the Rapier, Napier built a series of light 6-cylinder inverted in-line engines known as "E.97" of the 150 HP class, developing from these, the "Javelin" of 155/160 HP (mounted on Martin Baker MB1). The 165 HP Javelin IA and the 160 HP IIIA.

“Javelin III”

-In 1933, Napier acquired the construction license for the compression-ignition engines, that is, Diesel, from Junkers.

-Two of them, the Jumo IV and the Jumo V, were manufactured, receiving the names of "Culverin" and "Cutlass", respectively.

-The Culverin gave 820 HP. Later, the English Air Ministry lost interest in heavy oil engines.

“Napier Culverin”

-The "Cutlass" was of lower power, like the Junkers V.

-In the following self-designed engines we will see that Napier applied the sliding valve systems (influence of Halford), as we will see later.

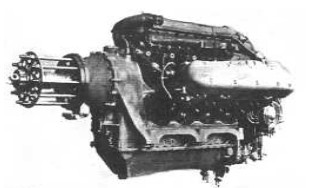

-Chief Designer Frank Halford was the designer of the next engine, the "Dagger2 that was derived from the Rapier.

-The Dagger is from 1934. It was a 24-cylinder vertical H delivering 635 HP, which reached 1,000 HP at 4,200 rpm (MB2 aircraft).

Halford got more power out of many small cylinders by spinning the engines at higher speeds. Like the Rapier, it had valves and two crankshafts.

“Napier Dagger”

“Dagger cross-section”

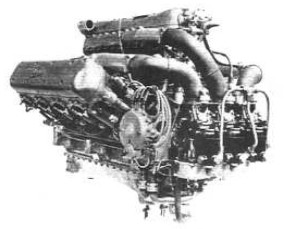

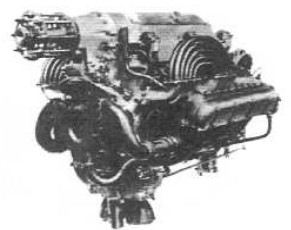

-In 1935 the formula in “H” gave way to the decision to build a 2,000 HP class engine, but as a horizontal H.

-This engine also had a double crankshaft and was called "Sabre"

-If the Dagger doubled the power of the Rapier, the Sabre doubled the power of the Dagger.

-The new engine passed the official tests of 100 Hrs at the BAM in June 1940.

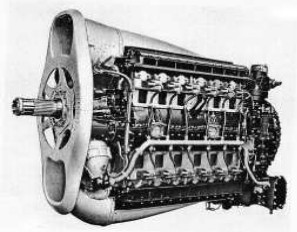

“Napier Sabre”

-It gave 2,200 HP of output and later in the VII series with two supercharger speeds it would reach 3,110 HP at 3850 rpm.

“Napier Sabre, right side view”

“Another view”

-However, the first installation of the Sabre was in 1940, on the Heston Racer for the World Record. But the Sabre's greatest success came from being used by the Hawker's Typhoon ground-attack fighters with 2,400 HP.

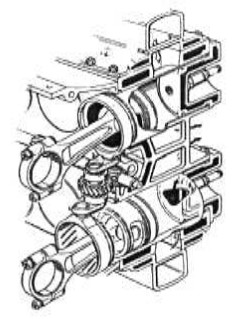

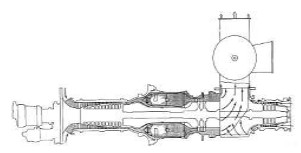

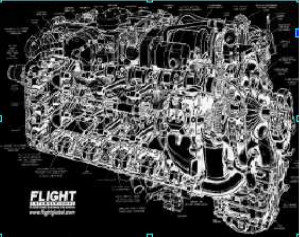

“Sabre system”

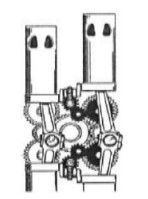

-The internal mechanism of the Sabre was extremely interesting. The sliding-sleeve type valves moved by gears on bearings. Some small crankshafts and connecting rods raised and lowered the sleeves, with a slight turn as well, making the sleeve ports coincide with those of the block, thus organizing the timing.

"Mechanism in vertical position"

-This important brand also advertised its products in the press as we see below.

“Logo in 1943”

-In 1935 the Dagger, a vertical H-engine, was closely related to engineer Halford, its designer.

“Dagger ad from 1935 and 1936”

“Napier Rapier VI ad”

-Another ad from Napier & Son Ltd. after WWII is the one below for the Sabre in 1947. It gave 3,000 HP.

“Napier Sabre ad”

-A little later, around 1952, Napier was already in full production of turbines like the ones that were advertised like this.

“Eland and Nomad ads”

-The Nomad was the brand's last piston engine, in fact it was a "compound" engine with turbocharger and also a coupled afterburner.

-Before these advertisements we have seen a more schematic representation of the Sabre mechanism together with the distribution-gear group from the crankshafts working synchronously. There we could see the two gear shafts that pass through the cylinder blocks to drive the sleeves.

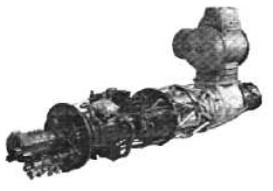

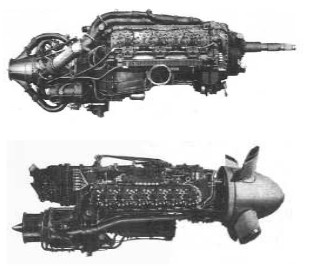

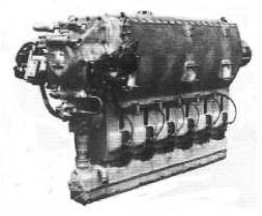

-At this point, Napier reaches the end of the war and immediately afterwards makes a new engine, the “Deltic”.

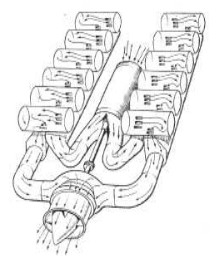

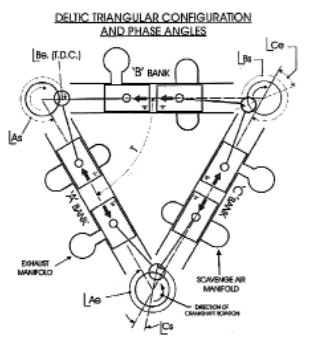

It was designed with the experience of the Culverin, the Diesel engine based on the Junkers Jumo 200 series with opposed pistons that was a cross between the Junkers 207 and 224. In turn they were based on the Junkers 223, with four joined 207 engines (see Junkers), In the Deltic there were three engines like the 207 joined by their crankshafts, as shown in the diagram below.

“Deltic schematic drawing”

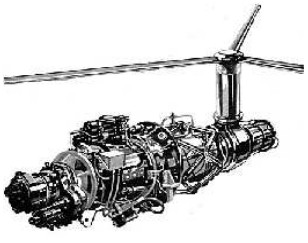

“Napier Deltic”

-It was of modular construction, which could be of 9 cylinders in total (3 x 3) or of 18 (3 x 6) or of 36 (3 x 12). And of course a double amount of pistons as each cylinder has two pistons. They were made with the aviation manufacturing system using light materials, but eventually they were mounted on locomotives and ships.

“Napier Nomad”

-Another engine that was in development at that time, and that was to be used in aviation for sure, was the Nomad. This was a Diesel engine that took advantage of the residual exhaust-gas energy using it to drive other turbines. In addition to driving a compressor as if it were a turbocharger, it was also connected to the propeller shaft through the front reduction gearbox.

“Nomad theoretical schematic drawing”

“Nomad, cross-section”

-It was a 12-cylinder, horizontally-opposed, boxer type engine. It was larger than the Sabre, resulting in a massive engine with 75 liters of displacement. It ran on the two-stroke cycle and it had no valves.

-The Nomad 1 gave 3,000 HP plus 300 pounds of thrust from the exhaust gases. It was tested on the ground in 1948, and in flight in 1950 on an Avro Lincoln. Fuel could be burned in the turbine which increased the thrust. They were multi-fuel: they could run on a wide range of kerosenes and gasoline.

-The Nomad 2 eliminated the transmission from the turbine to the gearbox for the contra-rotating propellers. The turbines and compressor were more developed.

“Napier Nomad 2”

-It gave 3,180 equivalent HP and with water injection it could reach a total power of 4,150 HP.

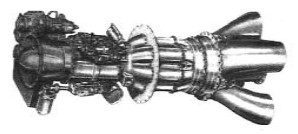

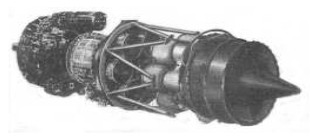

-At this point Napier was already working on turbines, its first realization being the "Naiad", a turboprop with an axial compressor and separate combustion chambers.

“Napier Naiad”

-The "Naiad" gave 1,500 HP to the shaft. There was a twin version, the 3,000 HP “Coupled Naiad”.

“Coupled Naiad”

-In those days the engines were built and developed by D. Napier and Sons Ltd. in their Acton factories. They no longer had the services of F. Halford who was working at DeHavilland. See.

-The Coupled Naiad were two Naiad joined through a formidable gearbox to drive two contra-rotating propellers. The Naiad in double version was developed under the direction of Chief Engineer Mr. H. Sammons.

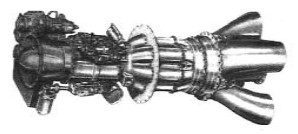

-The next turboprop with outstanding results was the “Eland”. There have been three different and main versions of this engine.

“Napier Eland -151”

-The one destined for the Fairey Rotodyne was the Eland model E-151 which was essentially a normal Eland to which an auxiliary compressor was added at the rear of the engine - visible in the photo, on the left - that fed propellant nozzles at the blade tips of this original large tonnage gyroplane. The Eland 6 delivered 7,300 shp.

“Eland”

-Another version was intended to equip aircraft such as the Elizabethan or to replace old piston engines on aircraft such as the Convair 340.

-The modified Convair 340 was renamed the Convair 540. For the four-engined Canadair the Napier Eland 504A was made, combining a “Power Egg” with the Eland and a Palouste turbine from Blackburn for starting, generating pressurized air.

-It was also mounted on the Varsity and Ambassador in the 3,500 Shp version.

“Two Napier Gazelles”

-The “Gazelle” was a new 1,250 to 2,000 Shp class turboshaft depending on whether it was intended for the Westland Wessex helicopter or the Bristol 192. Initially and before being perfected, it only delivered 800 Shp.

-It can be installed vertically or horizontally. The Gazelle 2 reached 3,300 Shp.

-The “Nymph” engine that delivered 535 shp (Shaft Horse Power) was abandoned after a long time of development.

-The “Oryx” engines are pressurized gas generators, 780/950 HP-Gas, it was a turbo generator, rather.

“Napier Oryx”

-The Oryx engines move a large volume of gases. They had a 12-stage compressor that fed five separate combustion chambers whose gases powered a two-stage turbine.

-The shaft of these turbines, which drives the main axial compressor, also drives the other side with a 4-stage compressor.

“Oryx schematics”

-To the combustion gases of the main engine, fresh air from this compressor is added giving a total flow of 6.5 Kg / sec. at maximum 400° C (752° F) rotating at 21,900 rpm.

-A double circulation valve directs this mixture in the open air or towards the nozzles at the end of the rotor blades of the helicopter.

-The operating principle of the Oryx is the same as the Eland 151 seen above. We reproduce the internal schematic of the Eland E-151 here to check the similarities.

“Eland-151”

-The E-151 was a turboprop plus air generator. But there is some similarity as we see when comparing said engines.

-When the Eland 151 engines were installed on the Fairey Rotodyne, combustion chambers were mounted on the rotor blade tips where the gases and air from the main engine were burned.

“Fairey Rotodyne”

-The Rotodyne carried an Elan-151 on each side. The propellers provided the advance speed, and the rotor the lift, including vertical takeoff and landing, which promised an interesting operation of this gyroplane.

“Blade tip chamber” (see Fairey)

-We see a detail of the combustion chamber that was on each blade tip. Air and fuel were provided through the inside of the blade itself.

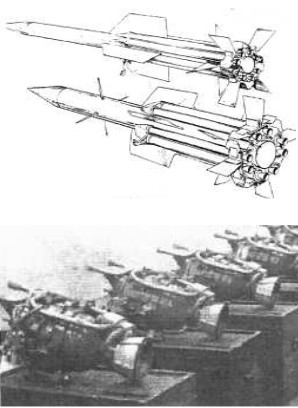

-Napier, like Bristol, Rolls-Royce and DeHavilland , built rocket engines with liquid fuel and oxidizer, designed to propel missiles, to support take-off or for momentary impulses in attack or climb.

“Scorpion”

-The NRE-17 was the Scorpion for piloted aircraft. The Ministry of Supplies decided to use hydrogen peroxide as an oxidant instead of liquid oxygen or nitric acid.

-The fuel was kerosene or gasoline.

“Double Scorpion”

-The Double Scorpion was the NSED-1, two identical engines coupled, just like the next Triple Scorpion which was the NSET-1.

“Triple Scorpion”

-With a third engine added.

-In 1957 Napier opened a subsidiary in the USA, Napier Engines Ltd.

-In 1959, D. Napier and Sons in Canada is established.

-In 1957 Napier collaborated with the Aerojet General Corp. for technical exchange of rocket engines using peroxides.

-For the missiles of that time, many of them were powered by ramjets, Napier also had its own as we see below.

“Misile with Napier ramjets”

-In 1961, in the midst of the aeronautical crisis in England and with the corresponding reorganization, Napier Aero Engines Ltd. was formed between the English Electric Company and Rolls-Royce to take over Napier's aeronautical engine business and the Acton engine factory. It was to continue with the Gazelle engines. In 1963 this company closed down permanently.

-The rest of D. Napier & Son continued as a subsidiary of English Electric working with the Deltic engine for naval and railway use.

-The Napier ad for RamJets and Rocket engines shown below is from 1956.

“Napier ad”

From Appendix 6: New Views for the Cub, Rapier and Dagger Engines.

“Napier Cub, 1000 HP”

-The Cub could be made up of two 90° V-engines positioned on either side, inclined, but with the upper cylinder blocks closer together.

-Another interesting engine was the Rapier with its vertical H cylinders, It had two crankshafts and was air cooled.

-It delivered a power of 385 HP at 3,900 rpm with reduction gear from 2.5625 to 1.

“Napier Rapier”

-The Dagger was another Napier related to designer Halford, which is why it is sometimes referred to as Napier Halford. The cylinders are in vertical H but with more power compared to the Rapier. It gave 100 hp at 4,200 rpm at 2,670 meters of altitude.

“Napier Dagger VIII”

-Regarding the Lion engine, we have located a reference of another model, perhaps derived. It is known as "Lioness", but without reliable data so far.

-De la serie de dibujos “Cutaways” excelentes publicados por la revista Flight traemos el correspondiente al Sabre. Ver el portal www.flightglobal.com para disfrutar de un centenar de motores diseccionados.

-From the series of excellent Cutaway drawings published by Flight magazine we bring the one corresponding to the Sabre. See the portal www.flightglobal.com to enjoy a hundred engine cutaways.

“Napier Sabre, cutaway in Flight Magazine” (PiP)

"Napier Lion from the Schneider of 1927"

-The engine manufactured by Napier but licensed by the RAF, the Raf3a model is like this one in the photograph taken at the Polish Air Museum in Krakow.

“Napier, licenced Raf3a”

-Next, a Napier Lion from 1918 in which we observe the unusual arrangement of the carburetors, very low and with exaggeratedly long pipes. This gives rise to oscillations produced by the vibrations, rather a ringing, and the need to heat the ducts to avoid external condensation or internal icing.

“Napier Lion of 1918”

“Napiers Lion on the Boulton Paul Bodmin”

-A rare installation of two Lion engines in a large plane like the "Bodmin" driving four propellers through a complex transmission - more typical on airships. Two pusher propellers and two pullers.

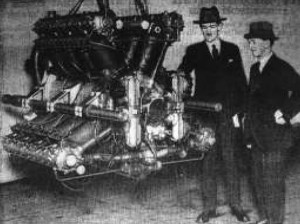

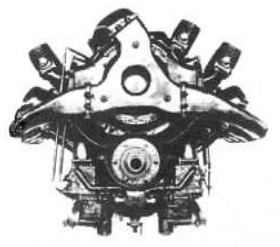

-Below we show an interesting photograph of the Napier Cub that gave 1,000 HP with 16 cylinders in irregular X seen from the front.

-Observing more closely we see that the cylinder banks on each side are at 90°, at 52.5° between the two upper rows and 127.5° the two lower rows.

“The Cub engine with two technical directors”

-Until this photograph we could not see the true size of this Napier Cub engine. In the illustrations in the main text it looks smaller, quite smaller.

-It was originally intended for the “Titania” seaplane, with four engines. It seems that they were going to replace the 600 HP of another model originally intended for this aircraft.

“Napier Cub front view”

-The arrangement of the cylinder banks is atypical in terms of their setting angles.

“Napier Cub side view with gearbox”

-The most important Napier product has always been the Lion W-engine, the one of the first era.

"Interesting front view of the Napier Lion"

-A cross-section of the Lion shows us very interesting characteristics such as that the crankshaft is floating on ball bearings.

-This engine (and like most) amazes us that despite its massive shape, it actually has very thin cylinder walls and liners. There is no excess material in the cylinder heads to withstand continuous operation and yet it happened.

-The ribs on the block also seem thin, despite having some formidable bed bolts.

-In October 1927, they already proclaimed the success of the Napier Lion engine that was prepared especially for the Schneider trophy, mounted on the Supermarine S.5.

“View of the Trophy engine”

-Below this motor is shown in the installation process. It was not only installed on the Supermarine S.5 but also on the Gloster IV.

-In these cases the rocker arm covers have a tapered shape to adapt to the faring lines.

“S.5 installatyion” (PiP)

-Apart from the Racing model, mentioned above, the Series 8 model also appeared.

-They gave 525 HP at 2,350 rpm and 567 HP at 2,585 rpm.

"Series 8, 3/4 front view"

“Series 8, 3/4 rear view”

“Napier Lion Series XI”

“Series XI, rear view”

-We take the opportunity to introduce some views of the Lion VII D Racing type, giving 1,275 HP at 3,600 rpm.

"The Lion VIID, really beautiful"

-From the E.97 new illustrations 3/4 front and rear.

“The E.97 Javelin”

-The "Sea Lion" variant was a Lion engine adapted for marine use in torpedo boats, rescue boats, etc. like the famous Vosper.

“Napier & Sons Ltd., Sea Lion”

-Of the Lion, extensively exposed, it turns out that other versions have been obtained now supercharged, turbocharged and an unknown -but mentioned in the main text-, the "Lioness".

“Napier Lion VI supercharged”

-The Lion VI was supercharged by a mechanically driven compressor.

“Un Lion V turbocharged”

-The turbocharging of the Lion V involved two intercoolers installed at the front of the engine to better exchange temperatures.

-We now come to the enigmatic "Lioness". They were inverted Lions, that is, with the cylinders down. The three cylinder banks were in an equal fan-shape.

-This was done with the intention of improving the pilot's forward visibility. It gave 500 HP at 2,200 rpm. Sometimes confused with the Lion "S" (the Lion VS was the V with Supercharger "S"). It is said that it was installed on a Fairey Fawn although there is no evidence of this.

“Lioness without supercharger”

“Turbocharged Lioness”

-We see some spectacular intercoolers.

-Another very significant engine -the Nomad- was the brand's last piston engine made with all the necessary accessories to obtain the maximum power from the machine.

-The one shown below delivers 3,000 HP of power on the shaft or shafts, as it has an output for two contra-rotating propellers. It also gives 320 lbf of thrust at the exhaust turbine outlet. It is a 2-stroke Diesel engine.

“Nomads con diferentes estilos”

-Not all Nomads followed the same architecture. The first gave 3,000 HP plus thrust with double propeller. and the one below gives 3,135 HP with a single propeller.

“Napier, 3,135 HP on bench”

-The standard consumption of aviation gasoline engines can be calculated around 250 gr/CV/Hr., Some above and others below. The Napier's consumption dropped dramatically to about 150 gr/HP/Hr of diesel.

-Below, in a cross-section of this engine we see the air intake and exhaust ducts and the cylinder ports for the two-stroke cycle. Compared to the four-stroke cycle, there is an effective stroke per revolution in each cylinder.

“Nomad cross-section”

-And to better understand the turbocharger we have another illustration. Both the turbine and the compressor are axial.

“Nomad circulation scheme”

-A nice section of the Nomad has been sent to us from this complex engine.

"Napier Nomad Details"

-This engine was at the limit of piston-engine development just before the full entry of turbine engines into the scene.

-It had twelve horizontally-opposed cylinders with sliding sleeves. It was a turbocharged Diesel with a compound overpower system. See main text.

-It gave 3,000 HP at 2,000 rpm.

-The four ducts on the Gazelle model 512 engine for helicopters are surprising.

“Napier Gazelle 512”

-In the mid-1950s, Napier supplied liquid fuel rocket engines for missiles such as those built by English Electric.

-For example the NRE.11 and NRE.17 installed on said missiles.

“Missiles with NRE.11 engines”

“NRE.17”

-Both NRE11 and 17 were similar as we see in the next cut.

“Napier NRE 11 and 17”

-The Napier Eland turboprop had turboshaft versions as well, and with many variants.

"Eland Turboprop at exhibition"

“The Eland for the Rotodyne”

-At the front, this Eland E.151 (NEI.3) drove the puller propellers and at the rear there was a coupled compressor for the air of the main rotor.

“Napier Eland 239A”

-The latter is the turboshaft version for commercial helicopter uses, etc. the rear outlet has a hydraulic coupling.

-We have received an illustration of the Napier Deltic, a cutaway for a better understanding of its architecture.

“Interesting cutaway of the Napier Deltic”

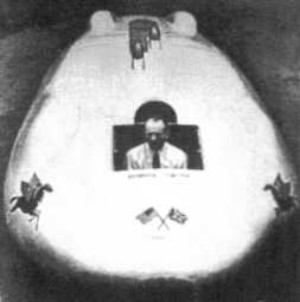

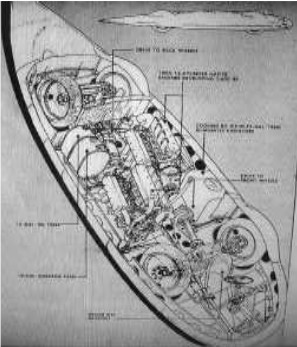

-We take the opportunity to show another application of the Lion to beat the land speed record. Year 1947.

"Mr. Cobb at the controls"

“Without the body work. The Napier engines were not aligned”

"Streamlined vehicle drawing"

From Appendix 7: Although the Deltic was never installed on any aircraft, the solutions were aeronautical in recent times: the 1940's.

-It was destined for railways and naval use. We have a schematic with interesting data.

"Deltic configuration details"

From Appendix 9: The Napier "Compound" engine known as the Nomad had two main variants.

-The Napier Nomad 1, more complex, with double contra-rotating propellers and a complex reduction box with a combination of the two reverse movements: that of the crankshaft and that of the compound power recovery system.

"Difference between Nomad 1 and 2"

-The Nomad 2 is more simplified.

From Appendix 10: Among the first built engines was also the Raf-3a. Below we show rocker-arm controls details at a Russian museum.

"See the threaded plug greasers"

From Appendix 12: Below we show illustrations of the “Oryx” gas turbine generator in normal version and with jet rotor.

"Two illustrations of the Oryx"

-From a German publication, the E-97 engine, precursor to the Javelin.

“Napier E-97, 150 CV”

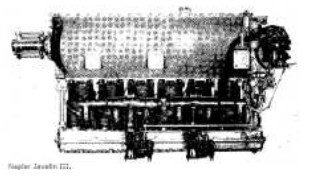

-The Javelin III shown below is is seen from the other side than the one illustrated in the main text.

“Napier Javelin III”

Engines of NAPIER

Model: Arab (Sunbeam Lic.)

Arquitecture:

Cooling:

Total Displacement:

Bore / Stroke: x

Power:

Weight:

Model: Cub

Arquitecture: 16-cylinder X-engine

Cooling:

Total Displacement:

Bore / Stroke:

Power: 1000 HP

Weight:

"Napier Cub, fig. 3"

Model: Culverin

Arquitecture: 6-cylinder Opposed piston engine

Cooling: Liquid

Total Displacement: 1737 cu. in.

Bore / Stroke:

Power: 820 HP @ 2000 rpm

Weight: 1785 Lb

"Napier Culverin, angled front view"

Model: Dagger

Arquitecture: 24-cylinder H-Engine

Cooling:

Total Displacement:

Bore / Stroke:

Power: 1000 HP @ 4200 rpm

Weight:

"Napier Dagger"

Model: Deltic

Arquitecture: Opposed piston engine

Cooling:

Total Displacement:

Bore / Stroke:

Power:

Weight:

"Napier Deltic"

Model: Double Scorpion

Arquitecture:

Chambers:

Fuels:

Feed System:

Ignition:

Thrust:

Weight:

Model: E-97

Arquitecture: 6-cylinder In line inverted

Cooling:

Total Displacement:

Bore / Stroke:

Power: 150 HP

Weight:

Model: Eland

Arquitecture: Turboprop

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: 7300SHP / ---

Weight:

"Napier Eland Turboprop Exhibition"

Model: Gazelle

Arquitecture: Turboshaft

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust:

Weight:

Power: 1250 to 2000 shp.

"Napier Gazelle 512"

Model: Javelin, -III

Arquitecture: 6-cylinder In line inverted

Cooling:

Total Displacement:

Bore / Stroke:

Power: 160 HP

Weight:

"Napier E.97 Javelin"

Model: Lion

Arquitecture: 12-cylinder W-engine

Cooling:

Total Displacement:

Bore / Stroke:

Power:

Weight:

"Napier Lion Series XI"

Model: Lioness

Arquitecture:

Cooling:

Total Displacement:

Bore / Stroke: x

Power:

Weight:

"Napier Lioness turbocharged"

Model: Naiad

Arquitecture: Turboprop

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust: 1500SHP / ---

Weight:

"Napier Naiad, cross-section"

Model: Nomad

Arquitecture: 2-stroke Horizontally opposed

Cooling:

Total Displacement: 75 Ltr.

Bore / Stroke:

Power: @ rpm

Weight:

Compound engine.

Nomad 1: 3000 hp + 300 lbf thrust.

"Napier Nomad 2"

Model: NRE-11

Arquitecture:

Chambers:

Fuels:

Feed System:

Ignition:

Thrust:

Weight:

Model: NRE-17

Arquitecture:

Chambers:

Fuels:

Feed System:

Ignition:

Thrust:

Weight:

"Napier NRE.17, drawing"

Model: Oryx

Arquitecture: Gas turbine

Compressor/s:

Combustion chambers:

Turbines:

Power / Thrust:

Weight:

"Napier Oryx"

Model: Raf-1a (Lic.)

Arquitecture:

Cooling:

Total Displacement:

Bore / Stroke: x

Power:

Weight:

Model: Raf-3a (Lic.)

Arquitecture:

Cooling:

Total Displacement:

Bore / Stroke: x

Power:

Weight:

"Napier, Raf3a license"

Model: Rapier

Arquitecture: H-Engine

Cooling: Air

Total Displacement:

Bore / Stroke:

Power: 380 HP @ 4000 rpm

Weight:

"Napier Rapier with front fairing"

Model: Sabre

Arquitecture: H-Engine

Cooling:

Total Displacement:

Bore / Stroke:

Power: 2000 HP

Weight:

Powers from 2,000 hp to 3220 hp, according to model.

"Napier Sabre, vista lateral"

Model: Scorpion

Arquitecture:

Chambers:

Fuels:

Feed System:

Ignition:

Thrust:

Weight:

"Napier Scorpion"

Model: Triple Scorpion

Arquitecture:

Chambers:

Fuels:

Feed System:

Ignition:

Thrust:

Weight: