Updated: 13-Feb-2020

From Appendix 6: In 2008, Continental introduced a new light Diesel for LSA (Light Sport Aircraft).

-For the imminent removal of gasoline AVGAS 100 LL by environmental regulations due to its lead content, the solution cannot be automotive gasoline or MOGAS.

-Because of the variable ethanol content and other compounds, it makes it unreliable for rigorous aeronautical uses.

"New small Continental engine"

-The solution is AVGAS gasoline engines that can run on 91/96 UL (UnLeaded) or Diesel with Jet-A1, as in this case.

-The engines that are intended to replace the old ones are the four-cylinder A-65, C-90 or O-200 engines. Up to 300 hp is expected in the future.

-Although brands such as ExxonOil have distanced themselves from having their kerosene used in aviation diesel engines since the Jet A-1 does not have the same characteristics as the usual Diesel.

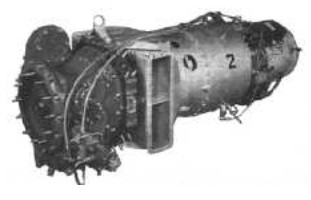

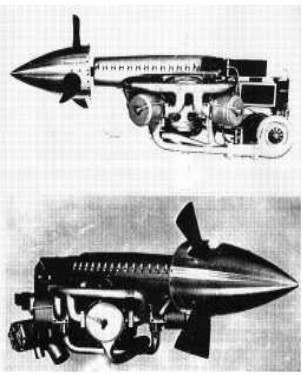

-Now, from CAE, Continental's Turbines Division, we have a picture of a small engine for UAVs and cruise missiles like the Tomahawk and Harpoon. It is the J-402-400 exhibited at the San Diego Museum.

-This is a small engine with a diameter of only 12.5 inches by a length of less than 30 inches. It was designed in 1971, and by the mid-1990's more than 10,000 units had been built.

"J-402-400 exhibited at San Diego Museum"

-Simple manufacturing, a transonic axial compressor followed by a centrifugal one.

-It had an annular combustion chamber and "spray" injection system, which was typical for Turbomeca engines.

-This architecture is not surprising since it is a much smaller scaled engine from the J-69.

-Starting is produced by a cartridge that generates large amount of gases affecting the turbine blades.

-The power at 41,500 rpm is 600 lbs. Subsequent versions like the -700, -701, -702 increased this power until reaching 990 lbs. of thrust.

-The -400s had only one hour of service life, enough for their outward journey.

-An interesting feature is its ability to start and run after having been stored for 5 years.

-To achieve this, the bearings were packed with grease or in boxes of oil.

-The -700s were reusable and had an improved lubrication system, but they had only 15 hours of service life.

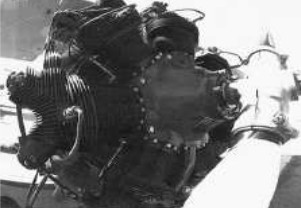

"Continental W-670"

-The W-670 gives 220 hp. A similar engine is shown sectioned at the San Diego Air & Space Museum, and has the interesting characteristic that the mother-connecting-rod is of steel and the other connecting rods are of aluminum alloy.

"Continental W-670, sectioned"

-In 1946 Continental presented a new line of 6 horizontally-opposed cylinder engines starting with the A-100. The new range was going to be 100, 115 and 125 hp. Later we would see that instead of the letter A, a C would be used: C-100, C-125, etc.

"Continental A-100"

-Being 100, 115 y 125 the power in hp.

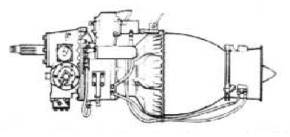

-We have found two engines, we did not know of until now, from the Turbmeca-built Continental turbine range, a turboshaft and a turboprop. Possibly Continental's own fruit.

“Two T-51”

-The upper turboshaft is the XT51-T-5 (Model 260-2) with 400 SHP and the turboprop below it is the T-51-T-1 (Model 210-1) with 280 SHP + 40 lbs of thrust.

-In 2008, with the proliferation of VLAs (Very Light Aircraft), Teledyne Continental has redesigned the classic O-200 engine that gave 100 hp, with improvements to adapt it to the current times.

-Recently certified, it has entered the sports aviation market, offering 100 hp of continuous power. (2008).

"New Continental O-200 version"

-With a total "dry" weight of 158 pounds, and with everything installed, including accessories it weighed 209 pounds.

-Although it preserves the general casting lines, we see a different oil collecting crankcase and a propeller plate of unusual design and unique by Continental.

-Among its most important options is the new Cessna 162 "SkyCatcher".

-It can run on AVGAS and MOGAS, aviation and automotive gasoline.

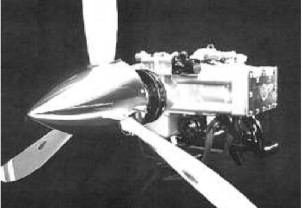

-There appears a small engine that is attributed to Continental and is used for small size UAV. It only gives 20 hp of power with a displacement of 16.7 cu. in.

"Continental 20 hp"

-It can certainly be 25-27 HP as it has growth capacity. It can operate up to 12,000 feet altitude.

-And now a less known turbojet TC-140 with an unmistakable air of French Turbomeca.

"El Continental TC-140"

-Three Continental Motors Corporation ads published in magazines such as Flying and Popular Aviation.

"Three Continental ads, around 1942"

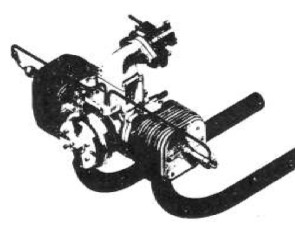

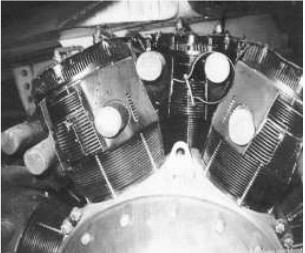

-Within a program, which was sponsored by NASA for the design of a light Diesel piston engine, Teledyne Continental proposed the one that we are going to show below. It did not come any further than a prototype without being commercialized. This was towards 1985.

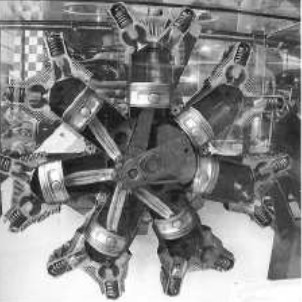

-The presented one was a two-stroke, four-cylinder radial engine. There were two versions, one in the classic vertical position with gear and the other one in horizontal position, like Salmson or Farcot, (See). Very original and beautiful in some way.

"The recently located Continental Diesel-radial"

-Of course, being a Diesel, it should be supercharged and besides, being two-stroke for which it is convenient to enforce the feed with a certain pressure and thus achieve a better sweep and filling of the cylinder.

-This in order to maintain the compression ratio at higher altitudes.

-The supercharger was a Turbocharger type in which Continental had already enough experience through its horizontally-opposed cylinder engines.

-The turbochargers are seen at the rear of the engines, as well as the large 100 Amp alternators.

“Horizontal radial at 90°”

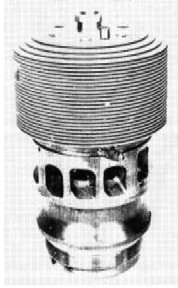

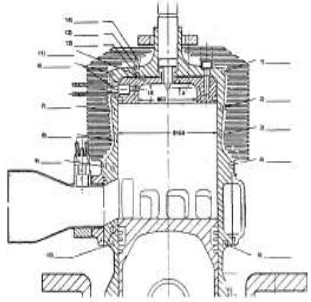

-With this type of engine the key is the cylinder. It has no valves but it does have ports. The injector is on the head and a collar surrounds the ports separating the inlet from the exhaust port.

"Continental 2-stroke cylinder"

"Collar that surrounds the ports"

-Most of the studies and also the difficulties that occurred were related to the cylinders. One of the reasons was the use of JetA-1 fuel that is not as lubricating as automotive Diesel.

"Cylinder diagram"

-And now a curious Continental engine application.

-This is a dual installation, ie two Continental C-85 engines superimposed with a Dick gearbox that joins the two engines' power output in a single output for the propeller.

"Cessna 172 with two Continental engines"

-Curiously, the propeller rotates in the opposite direction of the direction in which American general aviation propellers do.

-The propeller is a 108-inch diameter Sensenich.

-The appearance of the famous Cessna 172 Skyhawk becomes very disfigured and even a little bit ugly with this bulky hood.

-In 1947, a 14-inch diameter pulsejet installed inside a Curtiss Skeet fuselage was tested by the Navy.

“Skeet with pulsejet” (PiP)

They were used for artillery practices, and were manufactured until 1951. The latest models used McDonnell pulsejets.

-In the mid-1940's the Muskegon based Continental factory made auxiliary engines like the Tiny Tim, or the Mighty Atom of the Red Seal family.

-These engines were easily maneuverable and light. With starter and generator, like the engine in the photo, they gave good service, also around aircraft. Two-quarters of a gallon were enough to let the engine run for eight hours.

"Continental Tiny Tim"

-AEHS members have made pictures at the NASM to show more details of these almost unknown engines from this important brand.

-Continental XR-1740-2, cylinder details. Do not forget that they do not have valves but sliding sleeves.

"XR-1740-2 cylinders"

-Below, we show more photos that were made of the experimental Continental XR-794S.

"XR-794S bottom part"

“More general aspect of the previous engine”

“The LH side is wonderfully sectioned”

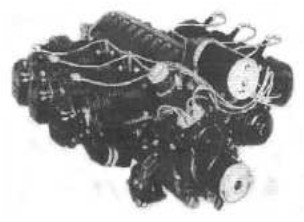

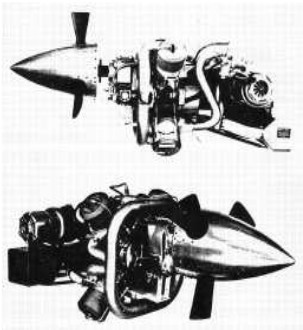

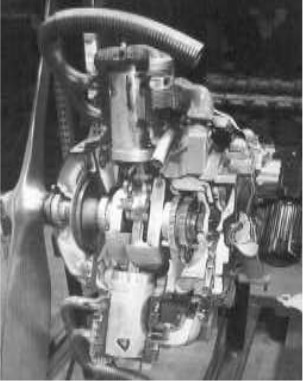

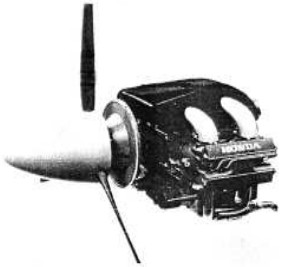

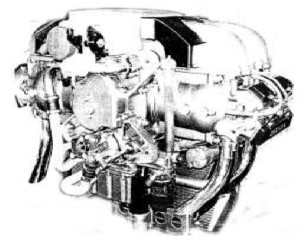

-TCM (Teledyne Continental Motors) and Honda Motor Co. collaborated in the study and design of the "New Generation" engine.

-The Teledyne Continental did so through the "relative" company Teledyne Technologies Inc.

-It was the horizontally-opposed, four-cylinder engine according to Continental's classic architecture. The engines were water cooled and prepared for using MOGAS fuel or unleaded automotive gasoline.

"The Continental/Honda engine with propeller"

-If Continental contributed its experience in aviation engines, Honda also contributed with its no less experience in motorcycles, cars and race cars.

-With 370 cubic inches of total displacement and 280 pounds of weight, it delivered 225 hp at 2,700 rpm.

-It could also use AV-GAS 100 LL aviation fuel.

-The author would like to point out that for an airplane, using automotive gasoline is not the right solution. Do not forget that each manufacturer is nourished from different sources and obtaining its anti-knock power is achieved with different additives, anti-knocks, etc.

-British Authorities limit the operating altitude for the appliances operating with this type of gasoline to a maximum of 6,000 feet. The reason is the fuel surface pressure that in automotive is not so seriously contemplated.

-The fuel surface pressure is a quality that prevents its vaporization. This happens more easily with the decrease of the atmospheric pressure at higher altitudes and also by heat, for example in ducts that cross from one side to another (pumps, filters, carburetors or injection) in the engine compartment.

“Engine view, rear side”

-Remember that lack of surface pressure creates the so-called "vapor lock" that interrupts the circulation of fuel through the ducts, stopping the engine.

Continental (Teledyne-Continental) did a NASA-sponsored program to develop an engine running on the Diesel system while using Jet fuel.

-The proposal was a liquid-cooled, two-stroke, horizontally-opposed, four-cylinder engine with 200 hp of power.

"Continental-NASA engine"

At the end of 2010 Continental Motors for aviation engines has been bought "Cash" by the Chinese AVIC International group. As from that date Continental is named "Continental Motors Inc."

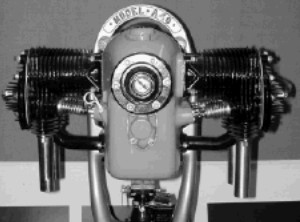

From Appendix 10: On the Internet we located a photograph for the four-cylinder A-40 (PiP) taken in a museum. This was the first engine that was made by this brand.

“Continental A-40” (PiP)

-It has "L" chambers and side valves.

-In a junkyard appeared a six-cylinder Continental for stationary installation (group generator of an APU, etc.).

"Photographed as it was"

Engines of CONTINENTAL Part 2

We have no more detailed engine information for this brand. We continue our search. Any help will be appreciated.