Updated: 31-Jan-2020

-The same situation as with the Phoebus, for which we could not find information, also occurs to the "Phoenix", the "Saturn", the "Zeus" or the "Orion" turboprop derivative: the "Zephyr".

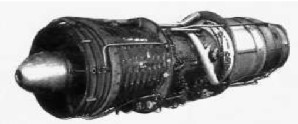

"Bristol Olympus I.11"

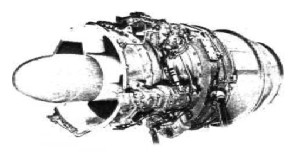

-The "Olympus" series is very wide. The early I.11 dual-compressor engines reached 5440 Kgs. of thrust at takeoff.

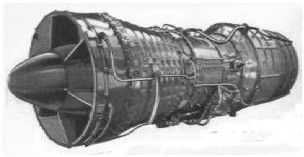

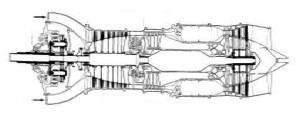

"Olympus 201"

-In the "200" series, 20,000 lbs of thrust was already exceeded. The "201" in the figure above had a solar type afterburner and delivered 10,900 Kgs. of thrust.

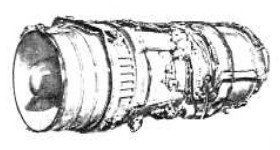

-The Mark 300 series, like the 301 with afterburner raised to 33,000 lbs of thrust. It was one of the most powerful British engines at the time (without being a turbofan).

-The "Olympus" was built in the US by Curtiss-Wright (see) and was designated J-67.

"Olympus"

-The Olympus were fitted on the British V-series bombers and were intended for the TSR-2 that was never mass-produced. Finally, the 593 model was installed on the Concorde.

"Olympus with afterburner"

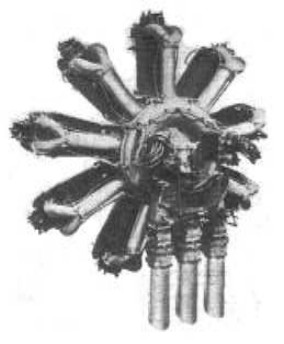

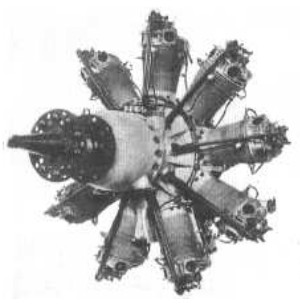

-The "Orpheus" is another important Bristol turbojet. Giving powers between 4000 and 8170 lbs.

-An extremely light engine, with a thrust/weight ratio of about 6 to 1, which was a very good result in that period.

-"Orpheus" engines have been fitted on more than 10 different aircraft, highlighting Orpheus Mark 701 on the Folland "Gnat" fighter, Mark 101 on the RAF's Gnat training aircraft, Mark 803 on the NATO Fiat G-91, Mark 805 on the Fuji T1A, and Mark 703 on the Hindustan HF24 etc.

"Bristol Orpheus"

-The BS-75, together with the BS-53 and BS-58 engines were built in 1960, and belong to the range of 7300 lbs. They were already equipped with a "Ducted Fan".

-Note that the engine designation is according to the period to which they belong: BE = Bristol Engines and BS = Bristol Siddeley.

"Bristol BS-75"

-They were inspired by Bristol-Engines and Armstrong-Siddeley components with tens of thousands of operating hours at that time.

"Bristol Sapphire"

-The Bristol "Sapphire" came from Armstrong Siddeley with reference AS-Sa71.R (the one that is shown) and was integrated in the Bristol production together with the "Python", "Mamba", "Viper" (P.187), etc.

-From Armstrong Siddeley aksi came other engines such as P.181 y P.182.

"P-182 cross-section"

-The AS P-181 and P-182, like the Viper, didn't have injectors but vaporizers.

-But Bristol also took over the engine production from DeHavilland and Blackburn. The latter brought along the French Turbomeca engines that were built under license.

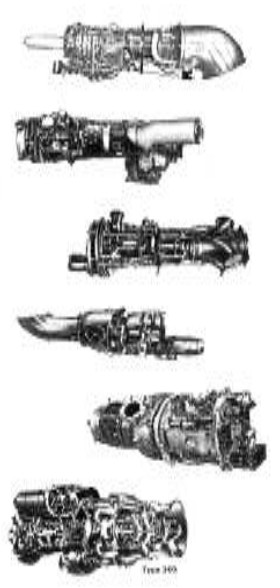

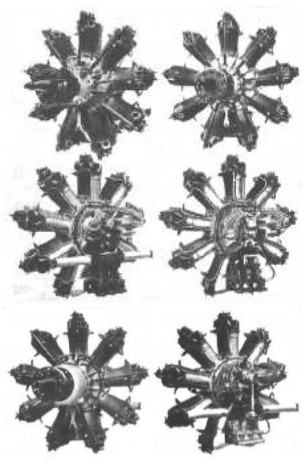

"DeHavilland engines"

-In the above illustration we show the "Gnome", "Nimbus", "Gazelle", "Artouste", "Palouste" and "Type 360", which were taken over from DeHavilland.

-Below we show another group of piston engines from Blackburn and DeHavilland.

-With all these engines Bristol's potential grew enormously.

"Engines from Blackburn and DeHavilland"

-Regrouping of British brands was due to the strong aviation crisis in that country in the late 1950's.

-Later Bristol itself, as has been said earlier, became part of the Rolls-Royce Group, with the full range of engines.

-And even RR had a difficult period later, but now, indeed, it is a major player in aeronautic engines.

"Bristol Viper"

-The Vipers and Gnomes gave Bristol important results.

-From the mentioned mergers, Bristol took over and developed the "Nimbus" for helicopters and began to investigate vertical takeoff. First appeared the BE-53.2, which would later be known as "Pegasus". This engine was installed on the "Harrier".

-The "Nimbus", as a helicopter powerplant, delivered about 685 hp to the shaft and was mounted on the Westland Scout and Wasp.

"Nimbus"

-The "Gnome" came of age in Bristol, giving 1400 SHP (Model H-1400), and it also equipped an important range of helicopters. There also was a "Double-Gnome" version.

"Gnome H-1400"

"Gnome P-1200"

-The use of the letters P or H before the Gnome's power specification was to indicate its destiny: Propeller or Helicopter. With subsequent power output.

"Double-Gnome"

-The "Gazelle" that reached 1600 SHP was for Westland helicopters. Less known are the P-181 and Type 360 that were also fitted on Westlands. This engine gave 1020 hp and can be categorized as a separate generation.

-The "Palouste" and "Artouste", built under license from Turbomeca, were used as auxiliary turbines.

-Bristol also manufactured the French turboprop "Astazou".

"Bristol Astazou"

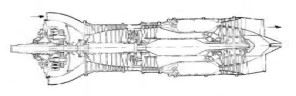

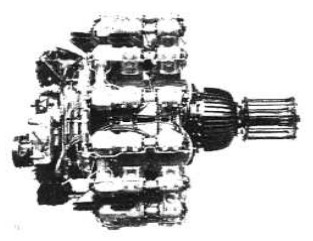

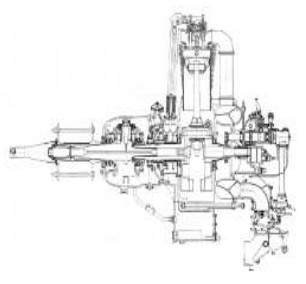

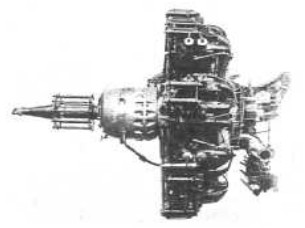

-The "Orion" turboprop (it seems that for this turbine they have retaken the name from Bristol's piston engine designs). It is a very interesting engine for having two shafts. The gas generator consisted of a 5-stage HP compressor driven by a one stage turbine.

-The LP compressor on the propeller drive shaft -through gear- was driven by a triple turbine.

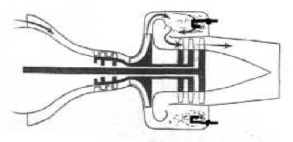

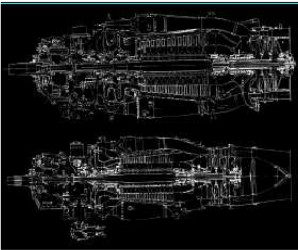

"Orion diagram"

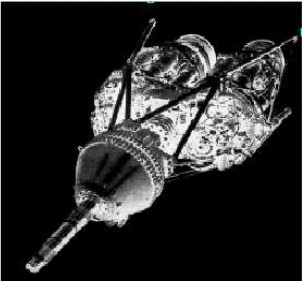

-Below we can see the Orion on a test bench.

"Orion"

-The power was calculated in 4,300 but it reached 5,150 SHP and able to maintain it at altitude without the need of using not designed means.

-It was known as BE-25.

-It was proven in flight on a Britannia plane, but precisely Proteus engines were already operating perfectly, so this project was abandoned.

-We are inisting on not to confuse this Orion with the Orion piston engine mentioned in the reciprocating engine section.

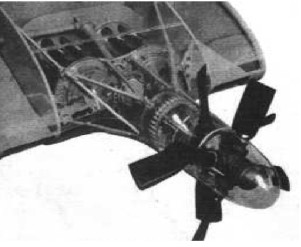

-And this is also the case of the "Pegasus", BE-53, which has been a famous turbine that received the name of another Bristol piston engine.

-They were installed on the military V/STOL aircraft Hawker P / 1127 and its derivative the "Harrier".

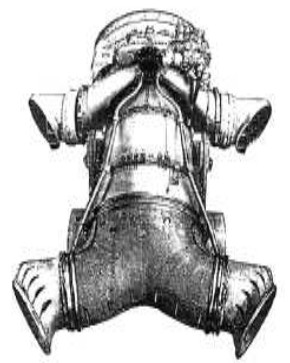

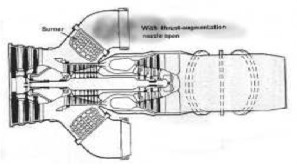

-It is an engine that has four outlets, two for the Fan and two for the exhaust. As they are adjustable, a vectored thrust occurs.

"Bristol BE53-2"

-In the image below we can see the blinds on the vectoring nozzles to direct the entire thrust flow in the desired direction.

“Pegasus”

-There have been many versions. Thus, the BE-53 led to other, more advanced, and more powerful engines like the BE-58, BS-100, etc.

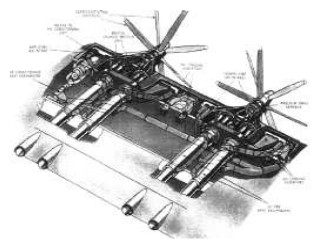

-Based on the BS-53 engine for the vertical takeoff Hawker P-1127 aircraft, Bristol Siddeley developed the BS-100.

"BS-100"

-With a thrust of 17,000 Kgs according to the French "Les Ailes" magazine of that time. It was specifically derived from the BS.53/16.

It had PCB system or Plenum Chamber Burning consisting of an afterburner in the cold air bypass of the front adjustable nozzles.

-Now we turn to other interesting engines such as Bristol's ramjets and rockets.

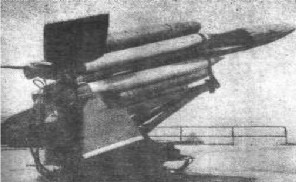

-In the ramjet range stands out the "Thor" that was to deliver 5275 lbs. of thrust at Mach 2.

"Thor"

-Thor's most interesting application may be the one on the "Bloodhound" ground-air missile. Below we see this missile with its solid-fuel "boosters" on a launcher.

-Logically, ramjets need high speed to be operational.

"Bloodhound"

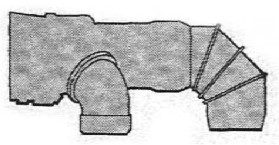

-Many ramjets have been built by Bristol: BT-30, BST-201, the BH, the "Odin", the RJ-824. Some of them did not go into production.

"BH ramjet"

-The "Odin", which was built in collaboration with Rolls-Royce, powers the "Sea-Dart" missile and because of its military nature its thrust was not disclosed.

"Odin"

-Another interesting ramjet, is the supersonic RJ-824.

"RJ-824"

-Bristol has also built rocket engines, both for launching objects into space and for propulsion aids. (See also Bristol-Aerojet). The most characteristic Bristol rocket engines are in the "Gamma" group.

"Bristol Gamma 201"

-Outstanding is the Gamma 201 (Mk-201) engine that powers the Black Knight. It has liquid fuel engines. The 301 is also a product of this series.

-The retractable Bristol Siddeley BS-605 was used for take off assist, climb, or combat on military aircraft. The PR-23 and PR-37 are also retractable and act as "boosters".

"BS-605"

-The "Spectre” and “Stentor” are larger.

"Bristol Spectre"

-All shown rocket engines run with liquid fuel, but through the "Bristol-Aerojet" division there are also rocket engines running on solid fuel.

"Stentor"

-The Stentor and Spectre, in a single "cluster" were the engines for the English air-droppable "BlueSteel" missile.

-The Bristol factories have had multiple locations, dedicated to specific models. In the main factory, in Filton, Bristol, they constructed the Viper 11 and 500, Odin, Thor, Pegasus, M-45 (with Snecma) and lately they reviewed Pegasus , Proteus, Viper, Orpheus, Sapphire, Centaurus and Hercules.

"Pequeño Bristol auxiliar"

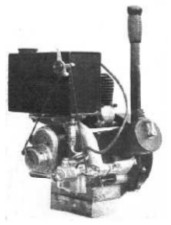

-And precisely Bristol also made auxiliary units that are capable of providing compressed air to facilitate large engines to start.

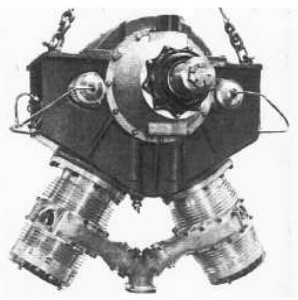

“Two types of Bristol airborne compressors”

-The first auxiliary unit is started by a pedal and the second one by a hand lever. The engine cylinder is upright, and the one that is inclined, is the compressor.

-Both units recharge a small pressured tank to provide the flow that is required for starting the aircraft's main engine(s) .

-As these are other engines fitted on board, they are included here. Besides, anyone involved in aircraft maintenance must be skilled in these machines as well.

-At Bristol-Siddeley Engines, in Hertfordshire, they built the Gipsy, Gnome H-1000 Mks-510 and 511, the Gnome H-1200 Mks-610, 640, 640A, 641, 641A.

"Gnome P-1200"

-Bristol-Siddeley Engines in Coventry was the base for the Olympus and Proteus.

-At Bristol-Siddeley Engines in Leavesden, they built the Coupled-Gnome (Double Gnome), Nimbus, Artouste, Gnome H-1400, Oredon III, Palouste, Gyron Junior, Goblin, Ghost y Gipsy. (see DeHavilland).

-The Olympus 593B and the M-45 were built in a Joint Venture with Snecma.

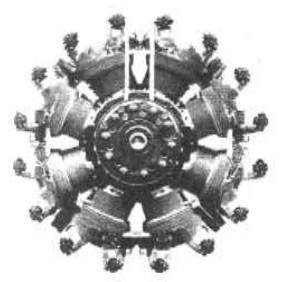

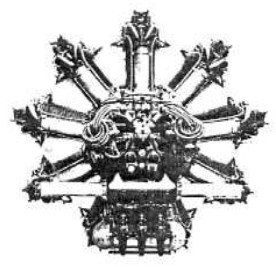

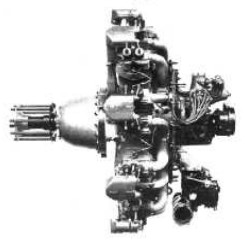

From Appendix 6: An interesting photograph with a rear view of a Bristol Jupiter. It is interesting because it is a turbocharged engine that had an output power from 420 to 460 hp.

"Turbocharged Bristol Jupiter"

"Bristol/Snecma at the Safran Museum"

-The Hercules in the photo above is uncovered and shows the impressive distribution gear train.

-This distribution is necessary for producing the rotation of the balls that drive the sliding sleeves up and down as well as left and right. A demonstrator of this movement can be seen in the Snecma/Safran Museum.

"Burt-McCollum demonstrator"

-Another interesting thing of the Hercules is that the crankshaft counterweights are acting as "Dampers". Normally, the masses opposed to the connecting rod system are floating (or at least one of them).

"Original Hercules dampers"

-From A.L.Kay's documented work we get a picture of the 5150 SHP Orion turboprop, aka BE.25 project, although it started with 3500 SHP.

-We also include a schematic diagram of the same engine.

“Bristol Orion BE.25” (PiP)

-Below we show a photograph of a Phoebus scale model. This engine is not presented in the main text.

“Phoebus turbojet” (PiP)

-They were preparing the presented Phoebus for a test flight with a Lincoln aircraft.

-With special attention to the side air intakes. The Phoebus was the turbojet version of the Proteus turboprop.

-We take the opportunity to show the differences between Proteus I and II by means of the diagram below that originates from the same publication as mentioned before.

“Proteus I y II” (PiP)

-And below another view of the magnificent Double Proteus. The photos, we obtained from RR Heritage Trust.

“Double Proteus” (PiP)

-This double engine was destined for the great Saunders-Roe "Princess" (SR.45) seaplane. Sometimes the Double Proteus is called Coupled Proteus.

-The Bristol company made designs for large motors, or rather, high powers towards the 1930's.

-We located two new engines: a 16-cylinder (two rows of eight cylinders) known as the Double-Octagon giving 1,020 hp at 6,000 feet. This engine is from 1931.

“16-cylinder Bristol”

-The two cylinder rows are facing each other cylinder to cylinder, instead of alternating in between.

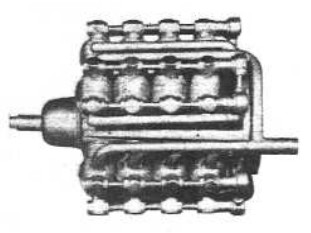

-And we also include the design of a 20-cylinder, radial engine with four rows consisting of five cylinders each. This is a drawing of the possible engine. The estimated power is 1,000 hp at 13,000 feet.

“20-cylinder Bristol engine”

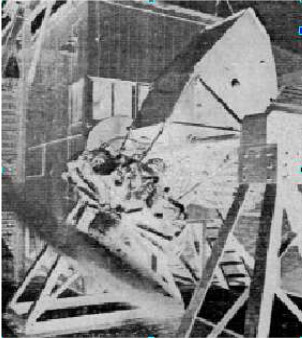

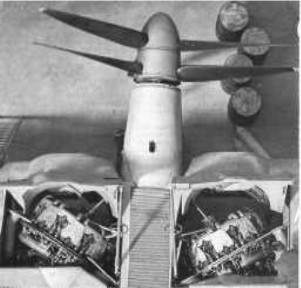

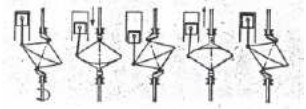

-Bristol used an interesting testbed with various positions for testing engines. In the picture we see a running engine swinging on a support.

“Photograph of the Bristol test bench” (PiP)

-When Bristol sleeve-valve engines were tested in the thirties, trials were made with different devices for studying and drawing conclusions, as shown below.

“two-cylinder unit for testing”

-Now an interesting picture of a Jupiter with three carburetors.

“The Jupiter with its three carburetors”

-The Mercury appears in the main text in a drawing. Below we enclose a photograph.

“Bristol Mercury”

-On the big Bristol Brabazon I aircraft, in the absence of major powers, they fitted twin-Centaurus engines, as we have seen in the main text.

-And on the Brabazon II, while being already available Proteus turboprop engines, they also installed twin engines as we see on the model in the figure below.

“Double-Proteus”

-The Double-Proteus idea was also repeated in the Double-Naiad and Double-Mamba. The formula involved the installation of two contra-rotating propellers.

“Bristol - 1951 vision for the 1954 Brabazón II”

-Two new B-25 views. In the beginning this engine was able to deliver 4,000 hp to the shaft.

“B.E.25 both sides at 3/4”

-By 1956 came the "Orion" turboprop, which was derived from the BE.25. It was little known because its use has not been disclosed.

“Two Orion views”

-The Bristol (ex Armstrong-Siddeley) BT.1 model was a ramjet that initiated the series, passing through the BT.2 to reach the most used Thor.

“ Bristol BT.1”

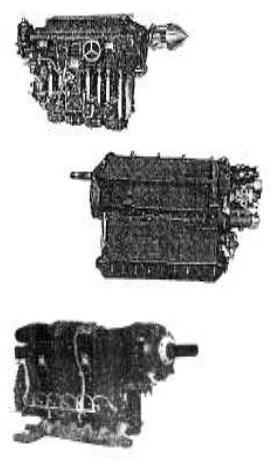

-Now we include an interesting photograph of the P.182 that was in the range of 1000 hp. This engine also appears in the Armstrong Siddeley chapter, because it is an engine (like the P.181) of the same architecture that was taken over by Bristol after the merger.

“P.182 turboprop”

“P.181 turboshaft”

-We note some similarity in the heat area between both P.182 and P.181.

-Recently we discovered a small Bristol engine that was used in target drones. It is the BS.347 with only 30 lbs. of weight for 140 lbs. of thrust. It was built in the mid 1960's.

“The beautiful small BS.347”

-Now we show a drawing of the small APU turbine that was made in a "Joint Venture" between Bristol-Siddeley and Germany's KHD. It seems to be a T-312.

“Bristol Siddeley / KHD, APU”

-Around 1978, Bristol made the supersonic Pegasus version for the VTOL Harrier aircraft. It had an afterburner on both front arms and a single adjustable nozzle for the two original rear outlets.

"The supersonic Bristol Pegasus"

"Vertical take off configuration"

"Horizontal flight configuration"

-Below we show the extraordinary Bristol "Taurus" XII version that is exhibited at the "Museu do Ar" in Sintra, Portugal.

-It has 14 cylinders in two rows and sliding sleeves. The exhibited engine is partly uncovered for a better understanding of the sleeve drive mechanism. All the sleeves, are visible from the distribution gear at the front of the engine, including the reduction gearbox.

"Bristol Taurus XII"

-We obtained another picture from a magazine that shows a twin installation of Centaurus engines on the Brabazon.

"Installation top view"

-We found an image of a Jupiter engine rear view, with a lot of details.

“Bristol Jupiter, rear view”

-The three carburetors and both magnetos are clearly visible.

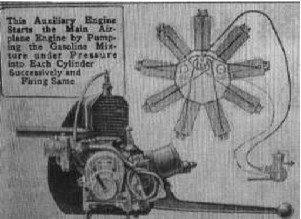

-The auxiliary motor was from 1922, and it had a hand lever to start it. It was used for starting the main engines. Interestingly this engine had a pump that drove the fuel mixture to the cylinders through ducts. With this mixture the first explotions for the final start up were produced.

-In the main text this engine is mentioned as a startup compressor, according to the information that was available at the time.

"Small Bristol starting motor"

-Returning to the successful Bristol Jupiter that was licensed by many foreign brands.

-The Jupiter Family has been very extensive with many series and all of them with their own differences and constant development.

"Part of the Jupiter family"

-The top images are from the VI to XI series that had powers from 415 hp to 460 hp.

-The cylinder stroke and diameter are the same in all of them; 7.50 inches and 5.75 inches respectively.

-The VIII, IX and XI series have epicyclic reduction gear at a 2 to 1 ratio. The others have direct propeller transmission.

The nine cylinders had a total displacement of 28'722 cu. in. The compression ratio was low for the time, according to the available gasolines: 5 - 6'3 to 1.

-Below we can see a better photograph of a Jupiter with its respectable reduction gear. In this Jupiter picture stand out the exhaust outlets at the front of the engine.

"A nice Jupìter"

-And we include a section diagram of this engine, so we can analyze it in detail.

"Jupiter cross section with gear"

"Bristol Jupiter VIIIF"

"A new nearly front view of the Mercury"

"And an interesting side view"

-The auxiliary unit shown before in this brand, the auxiliary starter, now comes in more detail.

-During the starting process, this small unit provides a rich fuel mixture under pressure into each cylinder of the main engine.

-The mixture is Injected at the exact igintion moment in the cylinder, the explosion makes the engine run.

-Thus they avoided risk of personal injuries that could be caused by turning the propeller manually when starting large engines.

"Engine and ciruit diagram"

-To make the injection take place in the corresponding cylinder, there is a "Delco" type distributor at the main engine itself.

-On the other hand there must be an auxiliary hand-moved magneto to send a reinforced spark at this moment in wich the main magnetos are not capable of generating a sufficient powered spark.

From Appendix 9: From the Bristol factory (and also from the mergers) there are a series of rocket engines to be confirmed with the main text.

-12KS10000

-15KS25000

-17KS12000 “Nihka”

-23KS20000

-26KS20000

-9KS11000

-9KS1660

-Bantam, -2 and -3

-BB7

-Black Arrow 3

-Excalibur

-Gamma, -2 and -8

-Lapwing

-“Nihka” (see 17KS12000)

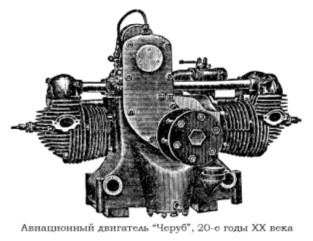

-With great enthusiasm I thought I had discovered a new Bristol engine, "Querubin", a small boxer.

“The Querubin in a Russian publication”

-It seems that this is one of the first Cherubs.

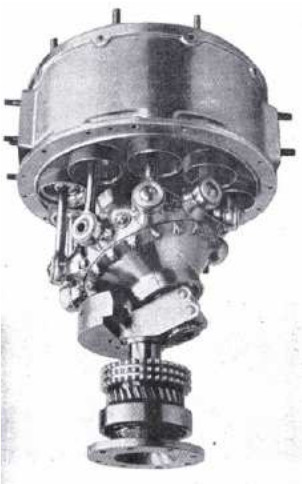

From Appendix 10: Towards the year 1936 Bristol made a barrel-type or revolver engine with the cylinders parallel to the driving shaft. With a system of an inclined plate that we see - uncovered - in the photo below. It gave 125 HP at 2200 rpm.

“With plate and crankshaft visible” (Arch. RMV)

“Operation diagram” (Arch. RMV)

-An interesting testbench at the Bristol factory, with the possibility of obtaining positions that later are repeated in flight.

"Testbench at Bristol Aircraft Ltd"

Engines of BRISTOL part 2

We have no more detailed engine information for this brand. We continue our search. Any help will be appreciated.