Updated: 02-Jan-2020

The Allison Engr. Co. at Indianapolis IN, was dedicated to the automotive industry since 1915. Founded by James (Jim) Allison, a risky businessman since he first invested in high quality and racing cars. This made him having the technical means and machine tools at his disposal to launch himself into the construction of aircraft engines later in 1926.

“Jim Allison”

-The logo of the new "Allison Engine Co." is a winged triangle with the letters A, E and Co. This company would enter the area of General Motors as "Allison Div." Nowadays it belongs to the Rolls-Royce group.

“Logos Allison”

-They started with piston engines derived from the Liberty 12 and these engines had the US Military designation: V-1410. First revising, Overhaul and modernizing. Previously during WWI, within the war effort, the car factory had built 250 Liberty-12-B engines.

-Therefore and because of an official order they developed two new versions of the Liberty-12-A, according to existing projects at the Air Service-McCook Field since 1924. These engines were air-cooled instead of water-cooled.

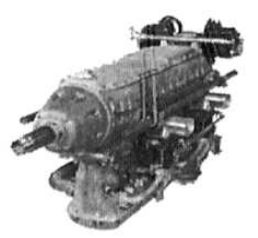

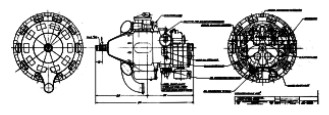

-Another view of the V-1410 engine with inverted cylinders.

“Allison V-1410 inverted V”

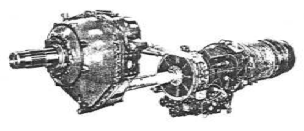

-The picture belongs to the Liberty version with gearbox giving 420 hp. There also was a water-cooled version.

-In the following year, 1927, they were commissioned to replace the German "Maybach" engines for American airships bought in Germany, the Macon and the Akron, but the jobs were suspended because of accidents.

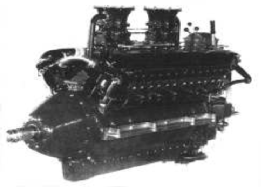

-This version should have the capacity to drive forward and reverse, through gearboxes, to be able to maneuver. They were the first Allison V-1710 versions, 12-cylinder, upright-"V", liquid-cooled.

-Still in 1929 they made a Liberty 12V based engine, with 12 cylinders and a displacement of 1650 cu. in. It was the V-1650 that gave 420 hp. The first V-1710, was tested in 1931. It was the -A version. The geared GV-1710-A.

“V-1710, drawing Lyndon Jones” (PiP)

-The V-1710 model had the following series: A, B, C, D, E, F and G. Each US Military specification corresponded to another manufacturer's, for example, V-1710-F25R was Allison's V-1710-173. The final letter R or L indicates if the engine turned clockwise or counterclockwise. (Right or Left).

-In 1931 appeared the V-1710.A that gave 650 hp (and the VG). It is easily reached 1,000 hp. Here are some examples:

| V-1710-B1 | = -4 | V-1710-B10 | = -23 |

| V-1710-C2 | = -5 | V-1710-C4 | = -7 |

| V-1710-D1 | = -9 | V-1710-E9 | = -47 |

| V-1710-E23C | = -137 | V-1710-E11 | = -93 |

| V-1710-F14R | = -61 | V-1710-F28L | = -123 |

| V-1710-F30R/L | = -111/-113 | V-1710-G4 | = -135 |

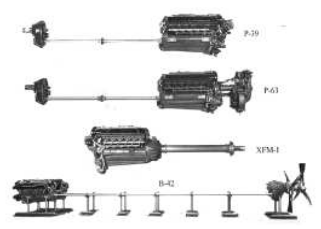

-And so on, up to many models with different arrangements and powers. Some of these engines are characterized by having a very long transmission shaft when they are installed in aircraft like the Bell P-39 Airacobra. They were built in large numbers for aircraft that were designed at that time in the thirties, such as the P-36, P-37, P-38, P-39 and P-40.

-Later they were installed in some P-51, double fuselage version instead of the Packard-Merlin (the -119).

-In 1938 the P-40 Warhawk and Tomahawk were famous. In fact during WWII it was the only liquid-cooled engine of American origin that was built in those years.

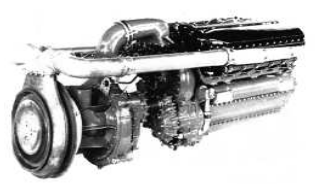

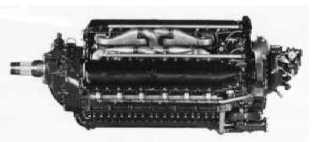

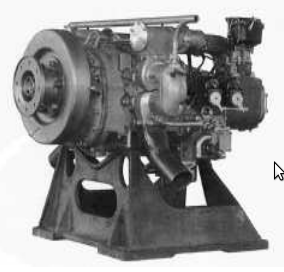

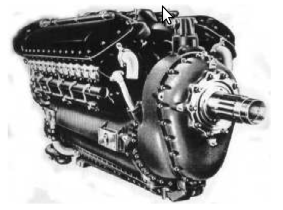

“V-1710-B1”

-The -4 (B-1) are Alison engines intended for the above mentioned airships. They could change the propeller's rotation direction in 8 seconds. They gave 650 hp.

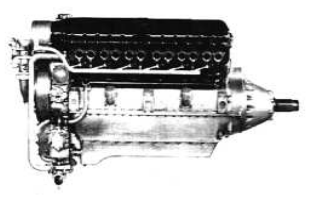

-In the V-1710-C the long gearbox also responded to a cosmetic issue when they were destined for the P-40. In 1937 they reached 1,000 hp.

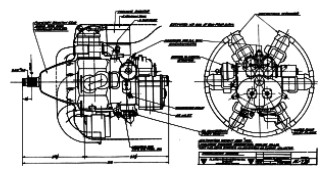

“V-1710-C series”

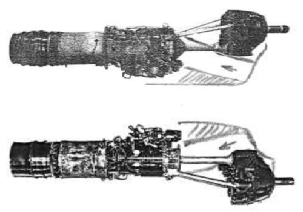

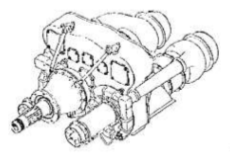

-The V-1710-9 was a -D1 used in rear locations for pusher propellers. An engine with this configuration was destined to the Bell XFM-1. The picture below has been downsized to be able to see the transmission.

“V-1710-9 (D-1)”

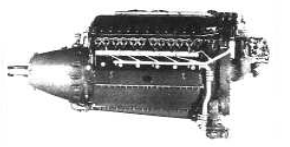

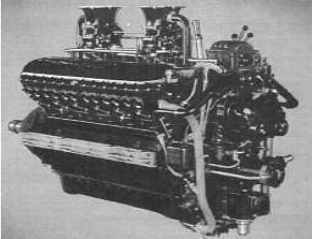

-The E Series were already more extensive and these as well as the F and G series added improvements over previous ones like crankshafts having counterweights.

“V-1710-E series”

-On both ends of the crankshaft superchargers or propeller transmissions could be coupled, as shown in the following E-11 version.

“V1710-E11 with supercharger”

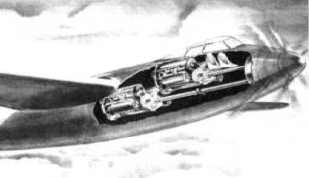

-The E-18 and E-19 which were installed in some of the Airacobra P-39 series, had a transmission shaft that went between the pilot's legs towards the propeller gearbox in the nose of the aircraft. The pilot was seated in front of the engine.

“V-1710-E18”

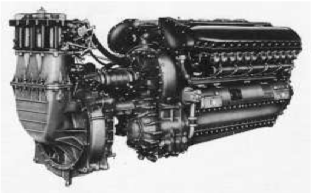

-The evolution of the "E" series was very interesting, from a single supercharger as seen above, up to the dual supercharger that was installed in the V-1710-127 (E-27).

-It had a WEP or War Emergency Power of 2,980 hp at 3,200 rpm up to 11000 feet and being able to go up to 26,000 feet.

-It is considered "Turbo compound" by bringing the exhaust gas flowing to the last step and its energy is added to the the mechanical supercharger-shaft and crankshaft.

“V-1710-127”

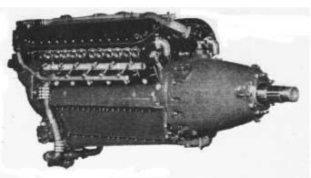

-The F series was as extensive as the E, and they were mounted in same successive aircraft series. Adding the first Lockheed P-38's.

“V-1710-85”

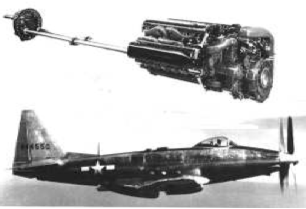

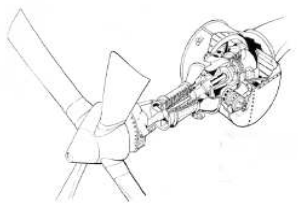

-In the V-1710-85 we see the installation of a cannon firing through the hub, thanks to an ingenious architecture that locates the engine behind the pilot.

-From the P-39Q Airacobra aircraft as exhibited in the USAF Museum.

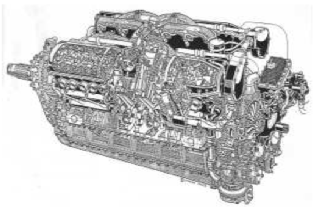

-The evolution of the "F" reached an extraordinary level with the F32 model (-119) inserting an "intercooler" or "aftercooler" as it was called at that time.

-Mind that it was liquid-cooled so effectively, that the supercharger outlet temperature halved.

"Allison V-1710-F32R"

"Allison -1710-115"

-The Allison -115 of this P-40 aircraft is the V-1710-F31R and as we see the rotation is clockwise or Right (always seen from the cockpit).

-The latest version of these engines was the -G, with the amendments incorporated from the E and F.

-The G-6 R or L was the V-1710-143 or 145 according to the propeller's rotation direction.

"Allison V-1710-G6"

-We can say that the V-1710 was the genuine Allison piston engine. From this engine they derived the V-3420, ie a "double V-1710".

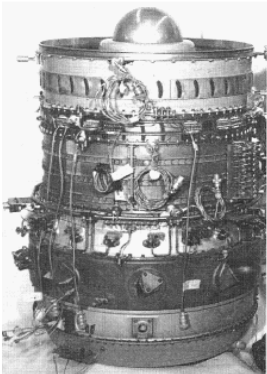

-But before reaching this new engine we should consider another one that showed up in the beginning of the brand's hisory, but whose design came from McCook Field. With 1,200 hp, it was the X-4520. It had 24 cylinders in four rows in "X", six cylinders each. It was put into operation by 1927 but no applications are known. Other information mentions that it reached the 1,500 hp.

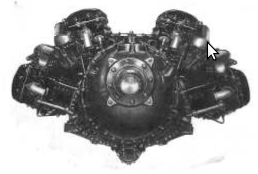

“Allison X-4520”

-It stands out that, being a high power engine, it was air-cooled as we can notice by the engine cowling directing air towards the cylinders. Therefore it also was lighter and needed less maintenance. However there were cooling problems.

-Geared, it was rotating at 2,000 rpm with about 1,500 hp of power. It had been exhibited at the Chicago fair in 1934 and today there is a model at the New England Air Museum, Connecticut.

“Allison X-4520”

In this museum there is a model of this engine in a reconditioning state and without air cooling baffles. There is another one in the R-R Heritage, that is restored.

-Because of the demand for more powerful engines for new military aircraft, both the Air Corps and the US Navy (USAF did not exist yet) ordered engines with higher specifications.

"DB-610 silhouette"

-Allison, just like the German Daimler-Benz used the formula to join two engines through a transmission.

-They did so joining two DB-601 (inverted V though) to obtain the DB-610, moving two contra-rotating propellers in one of their formulas and a larger single propeller. Allison joined two V-1710 through a transmission box that worked as a gearbox at the same time to drive one or two propellers as the case may be.

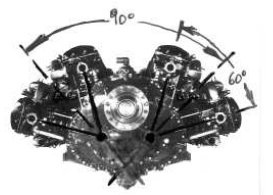

"Allison V-3420 silhouette"

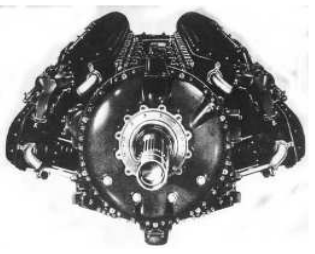

-Viewed from the front of the V-3420 we can clearly see that the two V engines are placed 60° to 90°, from each other. The two crankshafts end up in the frontal shaft gearbox where they are interconnected.

"Allison V-3420"

-This means that the two crankshafts are situated about 12-3 / 4 inches one from the other.

"Allison V-3420"

-There was a proposal with a single crankshaft but that required articulated rods. They made a wooden model that we see below.

"Allison X-3420"

-It remained only experimental. Although the degrees of separation between the V of each motor remained at 60o, the center line of both was 150°. They all had a total of 24 cylinders and power increased, according to model (A, B-1, B-2, B-3, B-4, B-5 B-10 etc.) to 2,600 hp (2,900 WEP ). Even 3,400/3,500 hp with water injection.

-These engines were installed in P-75s. The transmission to the propeller was original because it had two "booms" that reached the gearbox for the contra-rotating propellers.

"Allison V-3420-B"

-The collectors clearly point towards transmissions indicating that these engines were driving pusher propellers. In the figure below we see the rear side (in this case, the front) which has a big mechanical supercharger.

"Allison V-3420-B"

-A V-3420 as shown gave 2,600 hp at sea level and could give 2,300 hp at 2,3000 feet. After WWII the program was canceled.

-In 1947, Allison stopped the production of piston engines in favor of jet engines. In 1945 they had already started to build them.

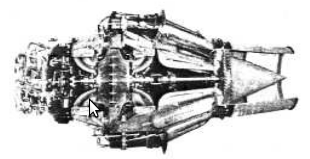

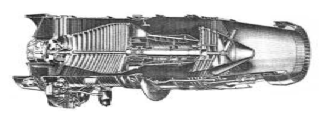

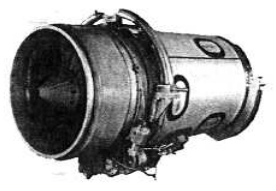

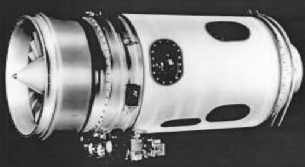

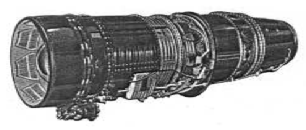

-The brand's first jet engine that went into production, was the Allison J-33. The version A-23 whose internal name was Allison Model 400C-5 (GE I-40 license) and it gave 4,600 lbs of thrust at 11,750 rpm that soon increased to 5,400 lbs.

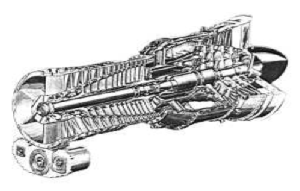

"Allison J-33 cutaway drawing"

-They built several versions before and after the above mentioned engine and the most famous of them was the J-33-A-35.

-That engine had a double-sided centrifugal compressor, following the Rolls-Royce "Nene" line, where they were derived from. They were mounted in the F-80s and T-33s. In fact it was General Electric that passed Allison the responsibility for making these engines.

“Allison J-33-A-16”

“Allison J-33-A-35”

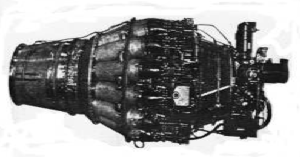

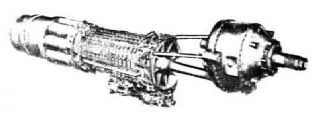

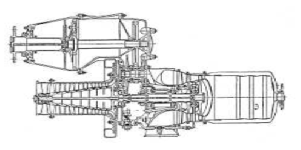

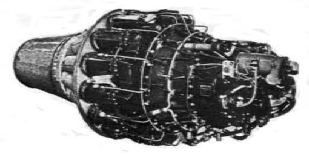

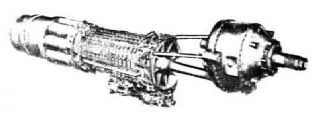

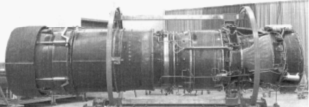

-En 1946 they did the same with the J-35 D.E. and it was called TG-180.

-It was quite different than the former ones because the compressor was axial instead of centrifugal. The thrust increased to an initial 5,400 lbs. and to 7,500 lbs. with afterburner.

“Allison J-35”

-Among others they were installed, in the F-84 and in the experimental XB-45 and XP-86, later known as "Sabre" F-86.

"Allison J-35-A-33"

-This J-35 does not have the nose cone, housing for the starter and other controls and accessories, and it does have space for an afterburner and a variable-area exhaust nozzle.

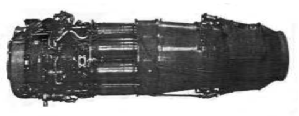

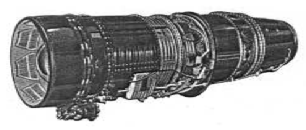

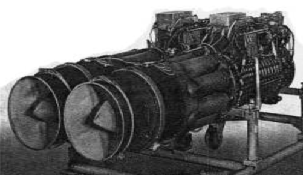

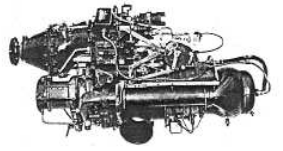

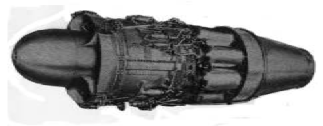

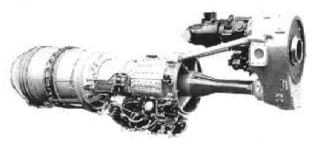

-With the experience gained with the J-35, Allison began developing the J-71 on their own and that engine initially was called J-35-A-23.

“Allison J-71”

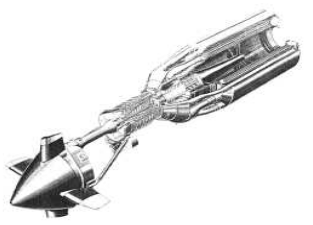

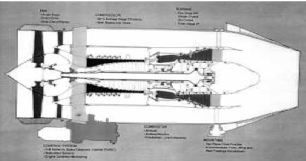

-It had a 16-stage compressor, 10 can-anular chambers and a 3 stage turbine.

-These engines were used in missiles like the "Snark" (assisted takeoff by Jatos) and they were also installed in the Douglas B-66 and McDonnell F-3.

-We see that it has an important axial compressor with 16 stages giving a compression of 8:1 and it delivers 160 Lbs/sec. or about 73 kg/s of air while it is spinning at 6,100 rpm.

-As stated in the text, the chambers are cannular, though better expressed as "can-annular". These individual chambers placed in a common conduit, were interconnected by ten tubes to balance them and spread at startup.

-With three turbines to drive the compressor, it produces 10,000 lbs to 14,000 lbs of thrust depending on working with or without afterburner.

“Allison J-71, seccionado”

-To cover tenders Allison built other brands' engines like J-25, J-34, T-63, etc.

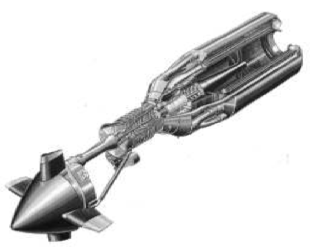

-Before entering the turboprops chapter, which is the real specialization in the brand's turbines, we mention an interesting experiment with an Allison supersonic engine by 1960, making use of high-energy fuel (borane) for missiles.

-Another interesting experiment was carried out by 1960 with another type of propulsion, a small ramjet known as Pyrodyne PD-37, used Pyrophórico propellant that inflamed spontaneously when it was exposed to air. There is only little information: It was small and also its thrust was about 36 Kgs. The fuel was TEA (Tri-Ethyl-Aluminium).

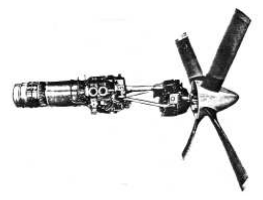

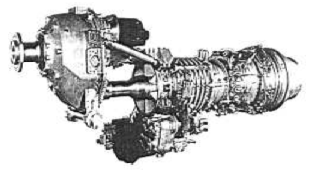

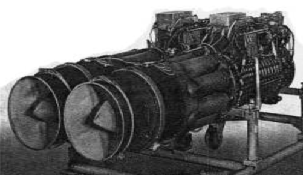

-Now we come to the turboprops. This is Allison's most worked field since the 1950's. At that time Allison had a turboprop of their own design, the T-38 with nearly 3,000 SHP (SHP = Shaft Horse Power).

"Allison T-38"

-To measure the turbine rpm soon they used "certain percent" and for the turboprop power the "Torque".

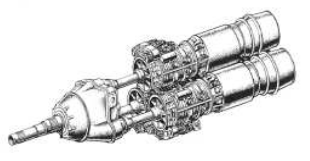

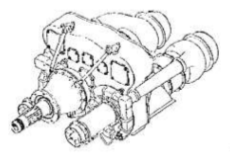

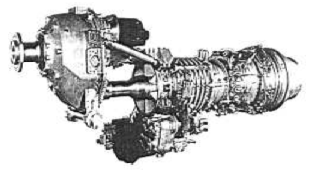

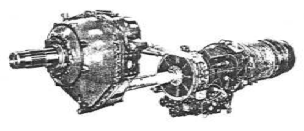

-Two T-38 engines joined by a gearbox gave rise to the T-40 with nearly 6,000 SHP.

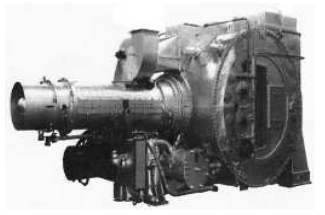

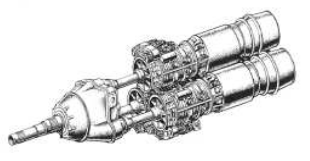

"Allison T-40"

-The T-40 had two transmission shafts, one for each engine and they were connected to the front gear box, that drove contra-rotating propellers.

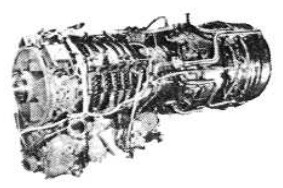

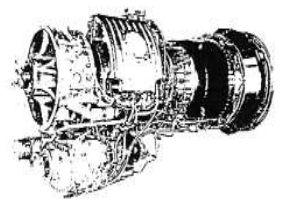

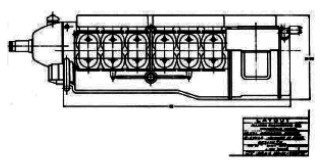

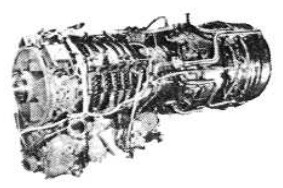

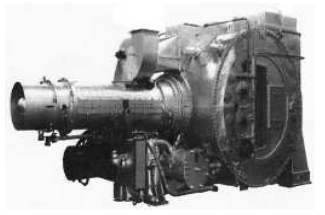

-The T-56 delivers about 3,500 SHP and it is the Allison 501's military version. They are mounted in the Lockheed Electra and Orion aircraft.

-It has an axial compressor and the chamber already is annular. Like most Allison engines, it has a separate gearbox.

“Allison 501, mounted in a Lockheed”

"Allison T-56 with propeller"

-This gearbox could be placed above the longitudinal axis of the engine, or below it.

"Allison T-56"

-The upper gearbox allows the air intake below the group (Case of the Hercules C-130, with high level).

"Allison T-56, upper and lower gearbox"

-If the box was below, the air intake was on the upper side. (case of Electra and Orion). The high or low wing aircraft design would decide the engine configuration.

-The T-78, of the same family as the above mentioned engines, has a heat exchanger for recovering energy from the exhaust gases.

“Allison T-78”

-A cutaway drawing of this interesting Allison engine (in this case the Detroit Diesel Allison Division). The T-78 is slightly based on the Allison 501 (T-56) as shown below.

"Allison T-78 cutaway drawing"

-So it is a turboprop with a heat recuperator around the exhaust nozzle to recycle part of the heat and energy that otherwise would be lost and add it to the air that already has left the compressor.

-Therefore it needs less fuel to reach the final required temperature.

-It seems that because of complication or weight, this engine was not effective enough to be successful.

-Based on the Allison 501 "core" (body), they derived the T-406 as well as the T-701. They were actually variants of different families and later, from these very models, other engines arose.

-For example, from the T-406-AD-400, the civil version GMA-2100. (General Motors Allison GMA) arose.

“Allison GMA-2100”

“Allison T-406”

-The GMA-2100 is a turboprop that is granted many properties as to have a gearbox with a reliability of 30,000 Hrs, light weight and wherein accessories and controls can be placed.

“Allison GMA-2100, cutaway drawing”

-The compressor with steel blades resists FOD impacts with wide tolerance.

-The combustion chamber is annular and does not produce smoke.

"Allison AE-3007"

-A part of the "GMA-2100" turboprop is used in the "AE-3007" high-performance turbofan. The "cores" of all of them are derived from the T-406. The AE-3007 delivers 7,000/8,000 lbs of thrust and a larger one is the AE-3012.

"Allison GMA-3007"

-The Allison GMA-3007 is another engine bound for high quality business jets and regional high speed aircraft. Some examples of these aircraft are the Embraer EMB-145 and Cessna Citation X. The GMA-3007 is the same AE-3007 with the current name of Allison Engines, former General Motors Allison and now owned by Rolls-Royce.

-As we see in the photo above it has six large inspection holes for inspection and LRU maintenance on the bypass duct cover. With FADEC.

"Drawing Allison GMA-3007"

-The GMA-3007 delivers 7,200 lbs. of thrust with a by-pass ratio of 5:1 and a pressure ratio of 23:1.

-These engines were installed in the Citation X that reach Mach 0.92, which is impressive for a civil aircraft.

“Allison 578”

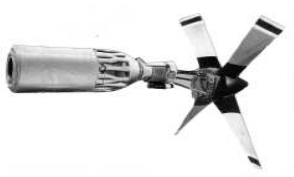

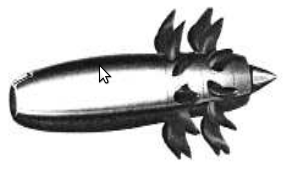

-The Allison-578 is also based on the "core" of the T-406 and T-701. it is a "propfan" in which the front turbofan is substituted by two contra-rotating propellers of multiple blades. Both propellers and gearboxes were built by Hamilton Standard, a renowned propeller manufacturing company.

“Allison T-701”

“Allison T-701”

-The T-701 is derived from the 501-M62. Note that the "T" specifications are military, but there is no doubt that the factory uses common parts with civilian versions.

-If we had enough space (and time) to describe the whole family of 501/T-56/T-703/T-406/GMA-1100/GMA-2100/AE-2100/AE-3007, etc. in a kind of family tree with all its branches, we could see how extensive Allison's production has been.

And also, during the years that these engines are in service, the millions of flight hours they have accumulated.

"Allison AE-2100"

-We have noticed that Allison changed its name to General Motors Allison (GMA) and then to "Allison Engines" Div. of GM (AE), as is the case of the new designations

of the above engines as the "AE-2100", "AE-1107", etc.

-Eventually, in 1994/5 the turbines Division is taken over by British Rolls-Royce.

-There is a "global" Allison engine and that is the Detroit Diesel Allison Division's "250". Its product range is wide and the turboshafts are predominating. These low and medium power engines (250 to 650 SHP, depending on the version) are used in helicopters and a few as turboprop in aircraft.

“Allison 250, diagram”

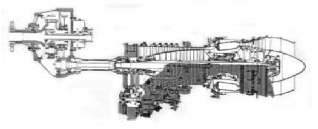

-The "250" concept is certainly original, the compressor is mixed: first axial and then centrifuged. From the diffusers, the compressed air and temperature are sent through two long ducts to a single "can-annular" chamber located at the rear of the engine. This chamber is inverted, which causes a new airflow turn.

"Allison 250, turboprop version"

-From the chamber outlet it flows to various turbines, depending on model, and the gases finally exit through a collector towards the top of the engine, generally, through two pipes ducted backward in the flying direction. This collector is located half way the engine.

"Allison 250, turboshaft version"

-Just before the exhaust outlet there is the drive outlet: reduction gearbox for rotor or propeller and also for accessories.

-The “250-C30” model exceptionally has a single centrifugal compressor.

“Allison 250-C30”

-Another interesting and logical version of their own development was the Allison 252. They coupled two Allison 250 to a single gearbox, maybe not exactly to obtain double the power for a specific aircraft, but to comply with the safety regulations for a twin-engine.

“Allison 252”

-The T-703-700 engine is not derived from the T-701, but it is a military version of the Allison 250-C30R (from the Bell OH-58D Helicopter). It delivered 650 SHP.

-Generally the US military designation for Allison 250 models is T-63. The best known versions are 250-B17 (400/420 SHP) and 250-C20 (420 SHP), which were installed in the Jet Ranger, Hughes OH-6 Cayuse and turboprop in the SIAI Marchetti SM-1019 (turbine version of the famous Cessna L-19).

-From the results of collaborations with other companies stands out the Rolls-Royce (RB-183) "Spey" production as Allison TF-41 for the USAF's Vought A-7 Corsair.

-Another joint program with RR was the RB580 engine.

"Allison 580"

-The collaborations with other companies resulted in new engines like the Allison/Garrett T-800 for the LHX helicopter.

“Allison/Garrett T-800”

-The CTP-800 is one of the engine family that was manufactured by Allison/RR and Allied-Signal/Garrett, which combines an undoubted technical excellence.

-The CTP-800-50 delivers 3,200 SHP.

"Allison/Garrett CTP-800"

-Allison Garrett also built the ATE-109/T-800, which is an engine that uses the the F-109 turbofan's "core" or power module from Alliedsignal/Garrett (and AiReresarch, of course).

"Allison ATE-109/T-800"

-From appendixes 2/3/4/5 and 6. We found a new and interesting group of this brand's piston engines.

-This is a small excerpt from a publication of the "RR Heritage Trust" written by a member of the AEHS and presented at the convention this group in 2009.

-We begin with a strange stationary horizontal four-cylinder engine, the U-250.

"Allison U-250"

-It has a displacement of 250 cu. in. giving 200 hp. Its main feature is that the cylinders are in two pairs connected through the head, in a "U" shape. It is liquid-cooled.

-Like other brands, Allison has a universal testing engine with one cylinder. The piston and rod were Liberty.

-The whole system was adjustable and variable in order to be able to test all types of cylinders, cylinder heads, valves, etc.

-Compression was variable, and so was the distribution, with the possibility of one or two carburetors and one or two spark plugs. They could change adjustments with the engine running.

“Allison's universal testing engine”

Another aero engine, which is unknown for not having been published, is the "400 I.G.".

-It used gasoline with the Otto cycle, and had 6 inverted inline cylinders. It had a displacement of 404 cu. in. giving 165 hp.

-They only made 1 or 2 engines of this type. This engine's most striking feature was that it used Prestone coolant.

-In the beginning, Prestone was an antifreeze liquid, which are so common these days.

-There are products capable of withstanding between -84oF a * 276oF.

"Allison 400 I.G"

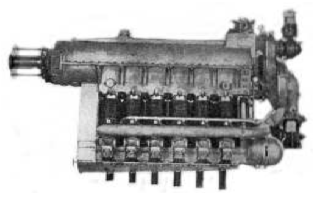

-Before the known V-1710-B they built one inline 6-cylinder engine destined for airships that gave 900 hp with 3,156 cu. in. They only built one.

"Allison Diesel engine for airships"

-Along the way of the V-1710s they built two Miami type engines.

-The first one was an inline four-cylinder water-cooled engine giving 5 hp. Only five of these engines were built.

-His bigger brother was already a V12 with a displacement of 2,138 cu. in. giving 425 hp. They built 8 engines of these. But we already see some traces.

"The Miami 12 engine"

"Allison V-1710-A"

-The Illustration of this V-1710-A engine is missing in the main text as it is only mentioned.

-They built some 70,000 V-1710 units during WWII period.

-The Following model was the V-1710-B for airships. We can see the controls in the upper back.

"Allison V-1710-B"

-The version for very high altitude may have been the V-1710-93 (E11) used in the P-63A with a two stage supercharger and a 3 body carburetor.

"Better sight of the Allison V-1710-93"

-Even more, with two mechanical superchargers and an exhaust-driven turbine that adds strength to the superchargers and engine shaft. "Turbo-Compound engine".

"Allison V-1710-127 (E27)"

"Allison mechanism for driving the supercharger"

-By having the first stage superchargers separated from the engine, it requires a transmission, and to compensate for misalignment this engine has universal type joints.

-There is also a hydraulic clutch of the kind that is used in automatic American car transmissions. This achieves speed changing performance by flooding the clutch with more or less fluid.

-The exhaust turbocharger gives additional thrust that in the case of using War Emergency Power reaches 150 lbs of thrust. (P-63H aircraft).

-The most characteristic feature of the Allison engine installations is the use of long transmission shafts to the propellers. But don't get it wrong, this is not an Allison design but a design that comes from the aircraft builders requiring these devices for their extreme aircraft models.

-There are cases of simple direct transmission and complicated solutions for twin engines, gearboxes for contra-rotating propellers, etc. as we will see in some examples.

"Various transmission examples"

-There is the classic Bell Airacobra assembly where the engine was behind the pilot on the wings. The transmission shaft passed between the pilot's legs.

-Furthermore, this arrangement could be fitted with a cannon firing through a hole in the center of the propeller hub.

-The exaggerated length of the transmission for the B-42 bomber is amazing.

-Another variation. It is a twin engine with two transmissions and a gearbox gears to drive counter-rotation propellers.

"Another complex installation"

-The engine shown below is a V1710 twin engine renamed V-3420 for a central engine driving pusher propellers.

-We can show an interesting installation of the V-3420 in the Fisher P-75.

"The V-3420 and the P-75"

-The V-3420s are the result of coupling two V-1710s with a single gear box at the front. In other words, we can say it is a "Double V-1710".

"View of thel V-3420"

-The last piston engine projects were to maintain superiority in the air. We show a case of a twin engine with two V-3120s.

"Drawing of a project based on Allison engines"

-We continue to discover surprises about this brand after the AEHS 2009 Convention was held in Indianapolis, where Allison is situated. The facilities were shown to participants including Allison directors gave their most interesting presentations.

-New engines that had not been spotlighted before, such as ramjets, pulse-jets, pulse-detonating jets and coal-burning engines were discussed in situ.

-Surprising was the first gas turbine already built in 1928 by Allison. The compressor, turbine and gearbox with the electric starter is displayed below. Only the combustion chamber is missing.

"The first Allison gas gas turbine with 200 hp"

-In chronological order we show the T40 consisting of a twin T38 engine.

"Allison T40"

-The T40A-10 version had a power that reached 5,260 SHP. It drove contra-rotating propellers.

-We have seen the installation of horizontal twin engines. There is another one with one engine above the other, as in the picture below.

"One engine above the other"

-This drive installation was used in the experimental XP5Y-1 airplane, which required precisely these extensions.

"View from the front of uncovered Allison engines"

-Absolutely original is the adoption of post combustion in a turboprop. It is supposed to increase the residual exhaust thrust.

"T40 with PC on the test bench"

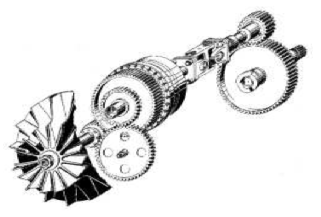

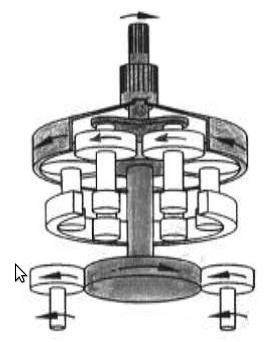

-In the case of coupled engines like the T40, the power outputs go to a common gear by means of clutches, then comes the planetary system for the double contra-rotating propellers.

"Front gearbox system"

-Wit the engine rotating at 14,000 rpm the reduction in the gearbox is at a ratio of 15.688 to 1 through planetary gears.

-We discovered that the T-44 is a power group concept with three engines.

"The T44 triple mounted"

-Another little known engine is an Allison driving a compressor for its use in helicopters or other devices like that.

"Compresor driven by an Allison"

-Now we see an Allison T-45 with heat recovery. Maybe a turboshaft.

"Allison T45, with recuperating system"

-Possibly the one below is a version of this engine or a variant.

"Similar engine but turboprop"

Engines of ALLISON (1st part)

Model: 12C25

"Allison 12C25"

Model: 250

"Allison 250-C18 fig.2"

Model: 252

"Allison 252"

Model: 400 I.G

"Allison 400 I.G"

Model: 400 IG

Model: 501

Model: 503

Model: 504

Model: 545

Model: 578-DX

"Allison 578"

Model: 580

"Allison 580"

Model: 615

Model: AE-1107

Model: AE-2100 (GMA-2100)

"Allison AE-2100"

Model: AE-3007 (GMA-3007)

"Allison GMA-3007"

Model: AE-3012

Model: ATE-109

Model: ATE-109

"ATE-109/T-800"

Model: CTP-800

"Allison/Garrett CTP-800"

Model: GMA-1100

Model: GMA-200

Model: GMA-2100

Model: GMA-3007

Model: GMA-500

Model: J-102

Model: J-33.

"Allison J-33-A-35"

Model: J-35

"Allison J-35"

Model: J-56

Model: J-71

"Allison J-71"

Model: J-89

Model: Miami-12

Model: T-38

"Allison T-38"

Model: T-39

Model: T-40 (500)

"Allison T-40"

Model: T-406 (AE-1107)

"Allison T-406"

Model: T-44

"The Allison T44 triple mounted"

Model: T-45

"Allison T45, with recuperator system"

Model: T-525

Model: T-54

Model: T-56

"Allison T-56"

Model: T-61

"Allison T61 with upper gearbox"

Model: T-63 (250)

Model: T-701 (501-M62)

"Allison T-701"

Model: T-703 (250-C30R)

"Allison 250-C30"

Model: T-78

"T-78 in a nice illustration"

Model: T-80

Model: T-800

"Allison/Garrett T-800"

Model: TF-32

Model: TF-41

Model: U-1240

"Allison U-1240"

Model: U-173

Model: U-250

"Allison U-250 fig.1"

Model: U-744

Model: U-749

"Allison U-749 engine"

Model: V-1410 (VG-, IV-)

"Allison V-1410 inverted V"

Model: V-1650.

Model: V-1700

"V-1700 aspect 1"

Model: V-3400

"El V-3400, a double V-1700"

Model: V-3420

"Allison V-3420-B"

Model: V1710

"Allison V-1710"

Model: X-250, -1, -2, -3, -D

Model: X-3420

"Allison X-3420"

Model: X-4520

"Allison X-4520"

Model: XJ-89

"Picture of the XJ-89"

Model: XJ-99

"The Short XJ-99 Lifter"

Model: XR-250

"Allison XR-250"