Updated: 17-Feb-2019

GYRO MOTOR

(USA)

We now have the 80 HP Gyro seven-cylinder rotary.

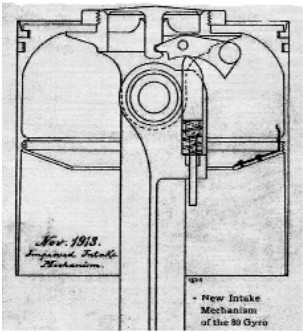

-By 1914 they already knew the constant faults of valves on piston heads used in the first models, such as those used by Gnome before adopting the "monosoupape" system.

-See Gyro and American Gyro.

“Gyro 80 HP engine”

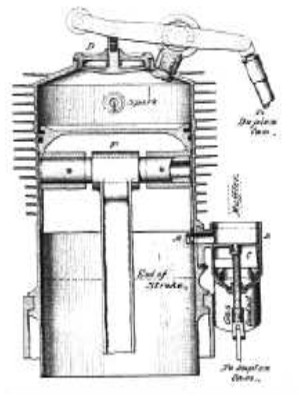

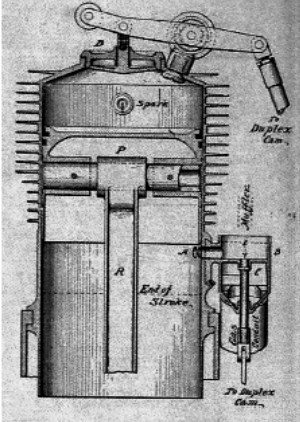

-Gyro Motors Co. invented a system called "Duplex" for its engines which had a piston valve on the cylinder side.

-This we can see in the below figure.

-The "Duplex Cam", or "double cam" controls both the side and cylinder head valve.

-Being the one on the cylinder head the main exhaust valve.

-The side valve uncovers some ports that act as exhaust if the small piston is in a lower position or as mixture intake when the piston rises.

“Gyro Duplex system details”

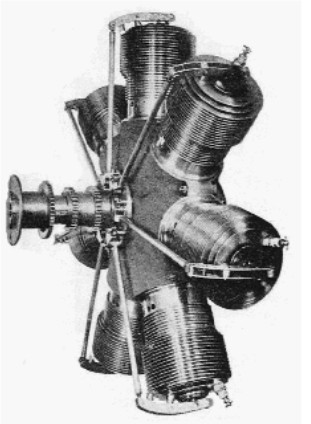

-In 1913, Gyro offered rotary engines like the one presented below, with 7 cylinders giving 80 hp.

-It used the piston type with an automatic intake valve in the head and a controlled exhaust valve in the cylinder head.

“The Gyro 7-cylinder, 80 HP rotary”

-Very strange is the position of the spark plugs on top of the cylinder head in a vertical position, which causes that in its interior, in a "bowl" form, due to the centrifugal force the oil accumulates, soiling it and producing misfires.

-We would not see this in successive models and in other brands.

-The lubrication of these engines was oil mixed with fuel,

-And not all the oil was burning, it was coming out of the engine periphery, expelled through the exhaust port when the valve opened.

“Two valve types used in the first Gyro engine”

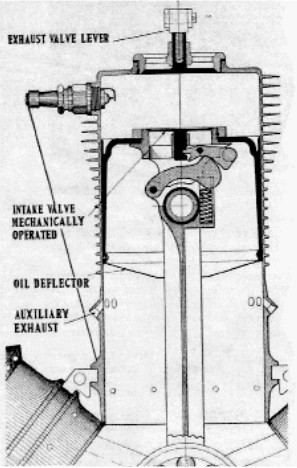

-In the second example we see that the auxiliary exhaust ports in the BDC, machined on the cylinder walls, are very elaborate: in a inclined downward direction facilitating the natural exit of the gases.

-We also see the spark plug in a more correct position. As in most rotary machines.

“Gyro Duplex system in 1914”

-More details on the Duplex system operation in the main text.