Updated: 11-Dec-2018

GENERAL ELECTRIC

(USA)

See GE for the main information and the list of engines.

From Appendix 6: Before introducing us more into a part of the GE engine evolution, we would like to provide a photograph of Sanford A. Moss when he was already in this company.

-He was an expert in overfeeding piston engines, in fact he was an American pioneer in the study of high-altitude flights.

“Moss with a compressor impeller”

-His experience was very important for the construction of General Electric engines.

-Although the first ones were built under British license, they soon continued with indigenous engines.

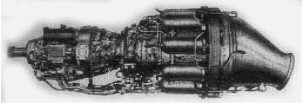

"The TG-100 was one of the first"

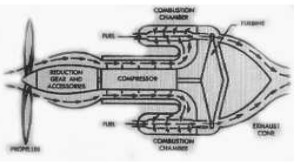

-The J-47 was an important and transcendental engine for the brand. It was used in the F-86 Sabre and the B-47. (1950's).

-Its variant with afterburner increased the power significantly, and was therefore installed on the F-95A with which it would reach 670 mph obtaining a speed record.

"Comparison of sizes for the J-47 with and without afterburner"

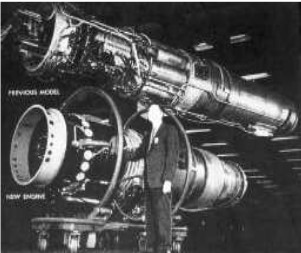

-The evolution went very fast because the J-47 of the normal Sabres were soon replaced on the F-86H by the smaller J-73 but with 50% more power.

"The J-47 above the J-73"

-The J-47 clearly has separate combustion chambers, however the J-73 has cannular chambers, which is the mixed solution of placing individual cameras inside a large annular chamber.

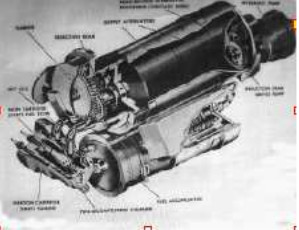

-For supplying energy to aircraft, GE made some APPs that were driven by a turbine to operate for a limited time.

-The fuel was stored in an accumulator, under the electric generator.

-A small combustion chamber and its turbine with the convenient reduction gear.

-On the other end of the generator there is a hydraulic pump for the flight controls, train, flaps, etc.

"An APP of the GE towards the year 1959"

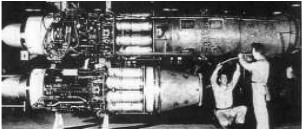

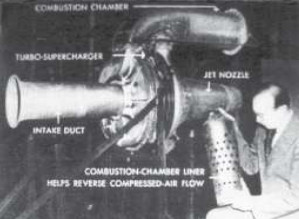

-Here show an engine built by an unidentified person, using a military turbocharger manufactured by General Electric.

-It is sufficiently described, and in his hands he has a flame tube that goes inside the combustion chamber.

-At the height of his right hand, we can see the fuel injector and the primary air inlet (the one that burns).

-In the skirt of the flame tube there are holes for the secondary air that is used to center the flame so that it does not damage the metal, and to dilute and lower the temperature to the limits of the turbine intake.

“Turbojet”