Updated: 29-Jan-2020

During WWI the Bentley rotary engines like the AR-1 (see Admiralty Rotary), the BR-1, BR-2 or Bentley-Humber, were prized for their performance and quality.

-In fact, they are based on the Clerget engines, improving them and lowering them in weight with aluminum alloy pistons, for example.

"Bentley Logo"

-In 1914, commissioned by the Admiralty, Walter O. Bentley began to study the Clerget's overheating, creating a variant with many changes, which was the AR-1 (Admiralty Rotary 1).

"Bentley-Humber"

-In 1915, it was redesigned with exterior aluminum cylinders, inner casting, and steel cylinder heads that were fixed to the casing by four long, obviously visible studs that were mounted outside the cylinders. They applied dual ignition and later the AR-1 that was modified this way, was renamed BR-1 (by Bentley-Rotary).

-This first engine was built at the Humber car manufacturer facilities.

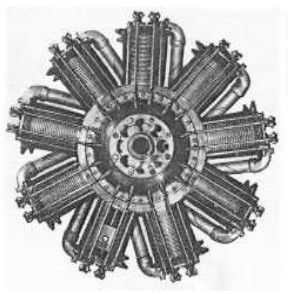

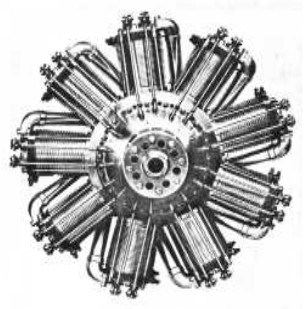

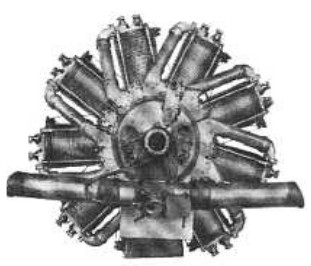

"Bentley BR-1"

-Aside from being built by Humber, they were also built by Gwyness as subcontractors.

-The BR-1 was a nine-cylinder rotary with a displacement of 1,053 cu.cm. giving 150 hp to 156 hp and maximum power at 1,300 rpm. They had ADS magnetos.

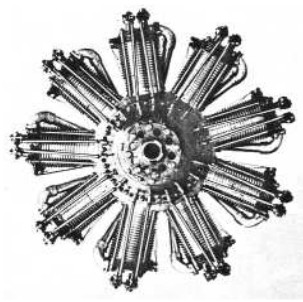

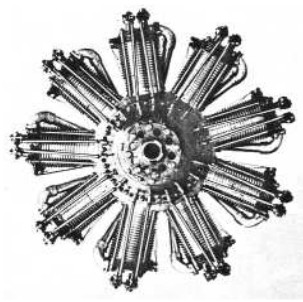

"Bentley BR-2"

-The Clerget neither ceased to be manufactured under license, and was massively built in the UK during wartime.

"Bentley BR-2

-Between 1916 and 1917, Bentley provided the even more powerful BR-2 (235 hp), which was a remarkable, immediate success and also a crucial point for the British rotary engines.

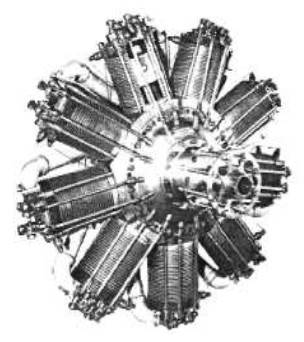

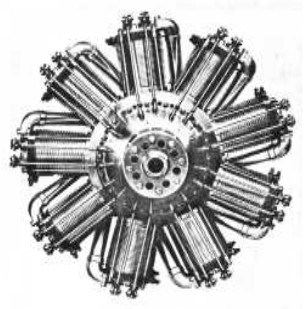

“BR-2, rear view” (in a different scale)

-In the picture with the rear view we see the two inlet air ducts to the centered carburetor, entering the engine block through the rear shaft.

-With the latest versions they reached 250 hp.

-Reaching this high power gave an idea of the improved construction, as in those days reaching 150 hp was a double row thing, because of various limitations.

-While their contemporaries were like the "Monosoupapes", the BRs used 2 valves per cylinder head.

-These engines were installed in Sopwith's Camel and Snipe.

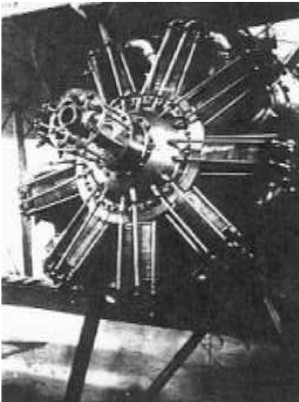

-From appendix 6: Below we show a photograph of a rotary engine originating from the Humber Works factory in Coventry. (See Humber).

"BR.1 or Bentley Rotary 1 from Humber"

"BR.2, installed in a Sopwith Snipe"

Engines of BENTLEY - ROTARY

Model: B.R.1

"Bentley BR-1"

Model: B.R.2

Arquitecture: Rotary

Cooling:

Total Displacement:

Bore / Stroke:

Power: @ rpm

Weight:

The BR-2 is an improved version of the BR-1. The first one delivered 235 hp and the later versions reached 250 hp.

"Bentley BR-2"